Tougher: All-new high-strength steel frame, high-strength aluminum-alloy body, more than 10 million miles of testing and Baja 1000-proven 2.7-liter EcoBoost® engine

Smarter: 11 new class-exclusive features, including 360-degree camera view, integrated loading ramps stowed in the pickup bed, 400-watt power outlets inside the cab, LED headlights and sideview mirror spotlights, and remote tailgate release

More capable: Up to 700 pounds less weight plus four engine choices for an impressive combination of power, capability and efficiency

Ford today introduces the all-new Ford F-150, the reinvention of America’s favorite truck. It is the toughest, smartest and most capable F-150 ever – setting the standard for the future of trucks.

The all-new F-150 delivers an impressive combination of power, capability and efficiency – from advanced materials that improve durability and inhibit corrosion, to faster processors that enhance driving performance, to breakthrough cargo management and towing solutions.

“F-150 is well-known for being Built Ford Tough. Now, it is both tough and smart,” said Mark Fields, Ford Motor Company chief operating officer. “The all-new F-150 redefines the future of trucks, and it is yet another example of our One Ford plan producing vehicles that serve customers with a commitment to the very best quality, fuel efficiency, safety, smart design and value.”

F-150 is part of the Ford F-Series truck lineup, America’s best-selling truck for 37 consecutive years and America’s best-selling vehicle for 32 years.

“We have a unique connection with our customers,” said Joe Hinrichs, Ford executive vice president and president of The Americas. “Time and again, F-150 has delivered the tougher, smarter features they want along with the capabilities they need for work or play. We build our trucks to their high standards.”

In designing the backbone of the F-150, Ford engineers improved the truck’s signature fully boxed ladder frame. It is all-new with more high-strength steel than ever – making it stronger and lighter. High-strength, military-grade, aluminum alloys – already used in aerospace, commercial transportation, energy and many other rugged industries – are used throughout the F-150 body for the first time, improving dent and ding resistance and also saving weight. Overall, up to 700 pounds of weight have been saved, helping the F-150 tow more, haul more, accelerate quicker and stop shorter, and contributing to efficiency.

“More than ever before, customers want a truck that is a dependable partner, mobile office and a go-anywhere workshop,” said Raj Nair, Ford group vice president, Global Product Development. “To meet the needs of our truck customers, we created smart new features and a whole new approach to using advanced materials and engines to improve capability and efficiency.”

Even tougher

The 2015 Ford F-150 is the strongest and most durable F-150 ever. Before it goes on sale, it will have been torture-tested in labs, at Ford proving grounds and in the hands of some of Ford’s most demanding truck customers for more than 10 million miles.

The grueling testing simulated the demands Ford’s customers will subject the truck to throughout its average lifetime. The tests include crisscrossing the country pulling heavy trailers and hefty loads through desert valleys and over high-altitude mountain passes – in temperatures from 20 degrees below zero to 120 degrees Fahrenheit.

Customers using the F-150 for construction, mining and utilities have tested and helped prove out its high-strength aluminum-alloy cargo box.

A disguised new Ford F-150 even raced in the Baja 1000, where it earned the distinction of completing all 883 grueling miles while some other purpose-built race vehicles could not.

To perform in these challenging conditions, the frame uses high-strength steel rated up to 70,000 psi – stronger than the steel found in some competitors’ heavy-duty pickup truck frames. Eight through-welded crossmembers provide increased stiffness, while staggered rear outboard shocks provide greater stability.

Even smarter

Several groundbreaking new productivity features debut in the all-new F-150, including many class-exclusives. They include:

360-degree camera view, using exterior cameras to create a bird’s-eye view of the truck to help the driver park, maneuver in tight spots and navigate down narrow roads and trails

Integrated loading ramps, which enable easy loading of ATVs, motorcycles and mowers

BoxLink™, which is a combination of metal brackets and custom cleats used to secure a variety of accessories in the cargo box, from ramps to storage bins to bed dividers

LED headlamps and taillamps, which provide excellent nighttime visibility

Trailer hitch assist, a new rear view camera feature that adds a dynamic line based on steering wheel angle in the display to help customers line up truck and trailer without requiring a spotter or having to get out of the vehicle

Smart trailer tow module, using an all-new smart trailer tow wiring harness that helps identify and inform the driver of potential trailer connectivity issues, burned or unlit trailer marker lamps, and brake light and trailer battery faults

Remote tailgate, allowing for the tailgate to be locked, unlocked and released with the key fob – eliminating manual locking and increasing convenience and security. The tailgate also is damped, dropping down, hands-free, to a flat position when opened

High-wattage power outlets (400 watts, 110 volts) in the cab, allowing drivers to easily charge corded tools, battery chargers or mobile devices on-site or while driving

LED spotlights on sideview mirrors, which provide powerful, durable and bright lighting around the truck exterior

Latest EcoBoost® technology in an all-new, even more efficient 2.7-liter EcoBoost engine that features extremely high output and lightweight design

Next-generation tailgate step, which is now fully integrated inside the tailgate and virtually invisible when not in use

Other smart innovations include:

New 8-inch LCD productivity screen in the instrument panel, which includes updated truck apps – from fuel economy to towing tips – and the ability to create a customized home screen for customers to access their most frequently used apps in one place

LED lighting embedded in the walls of the cargo box, which brightly illuminates the box interior to help customers quickly find tools or other items

Rear under-seat storage in F-150 Super and Crew cabs, providing hidden storage for valuables. Two storage bins also are located underneath the rear seats

Boxside step, now available for the short 5.5-foot box

They join available driver aids, including SYNC® with MyFord Touch®, hill start assist, MyKey®, rear view camera, reverse sensing, trailer brake controller and extendable tailgate step.

More capable

In addition to helping customers work smarter, F-150 features segment-first technologies that automatically assist drivers. They include:

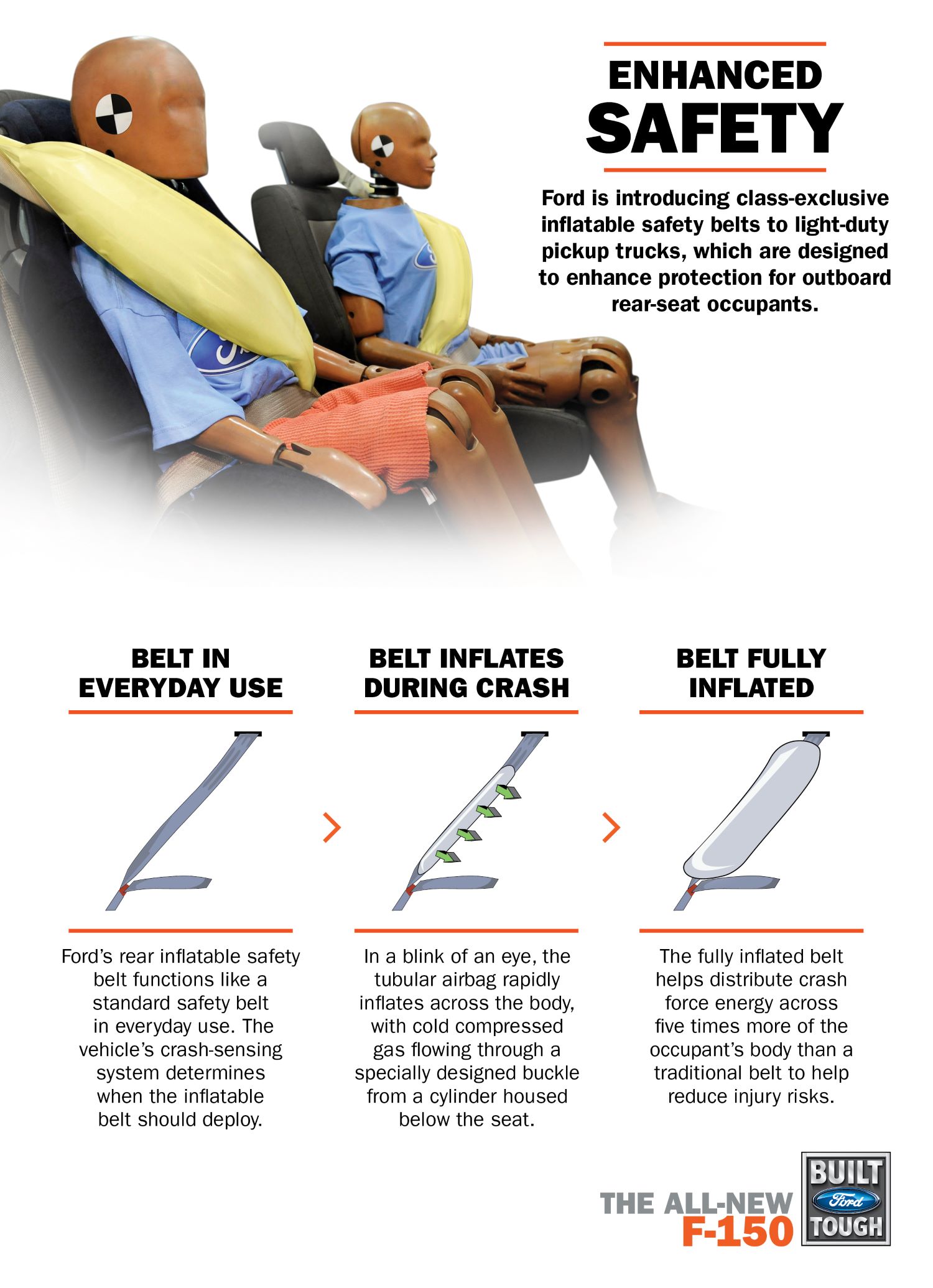

Second-row inflatable safety belts, which work like a traditional belt but include a tubular airbag that inflates in the event of a crash and distributes the force of the impact across a wider area of the passenger’s chest

Curve Control, which automatically provides more aggressive four-wheel braking when the truck is going into a corner too fast

Adaptive cruise control, allowing drivers to set a cruising speed and use radar technology to monitor traffic ahead and maintain a safe distance between vehicles

Lane-Keeping System, which is designed to help avert unintentional drifting of the vehicle outside the intended driving lane by automatically detecting the left- or right-hand road lane markings using a camera mounted between the windshield and interior rearview mirror

Blind Spot Information System with cross-traffic alert, which uses radar hidden in the taillamps to detect a vehicle entering a driver’s blind spot while driving or backing up

A range of four engines provides more power to meet almost any customer need.

A new 2.7-liter EcoBoost with standard Auto Start-Stop and a 3.5-liter V6 engine with twin independent variable camshaft timing join the proven 3.5-liter EcoBoost and 5.0-liter Ti-VCT V8. The 2.7-liter EcoBoost engine features a lightweight, compact design to deliver the same power as some mid-range V8s.

Auto Start-Stop technology helps save fuel. Unlike start-stop solutions in other vehicles, this technology – specially tuned for truck customers – shuts off the engine to save fuel when the vehicle is stopped, except when towing or in four-wheel drive. The engine restarts in milliseconds when the brake is released.

Ford F-150 trucks equipped with EcoBoost engines also will benefit from standard Active Grille Shutters. Active Grille Shutters stay open when extra engine cooling is needed, such as during low-speed stop-and-go driving or while working in hot weather. They automatically close to reduce aerodynamic drag at cruising speed.

On sale late this year

When it goes on sale late this year, the all-new Ford F-150 will continue the tradition of offering the broadest selection of trim levels in the full-size pickup segment. Five primary trims are available: XL, XLT, Lariat, Platinum and King Ranch. Chrome appearance packages are available with XL, XLT, Lariat and King Ranch. Monochromatic sport appearance packages are available with XL, XLT and Lariat.

The FX4 off-road package can be added to most four-wheel-drive models, improving trail capability with an electronic locking rear axle, skid plates and off-road-tuned shocks.

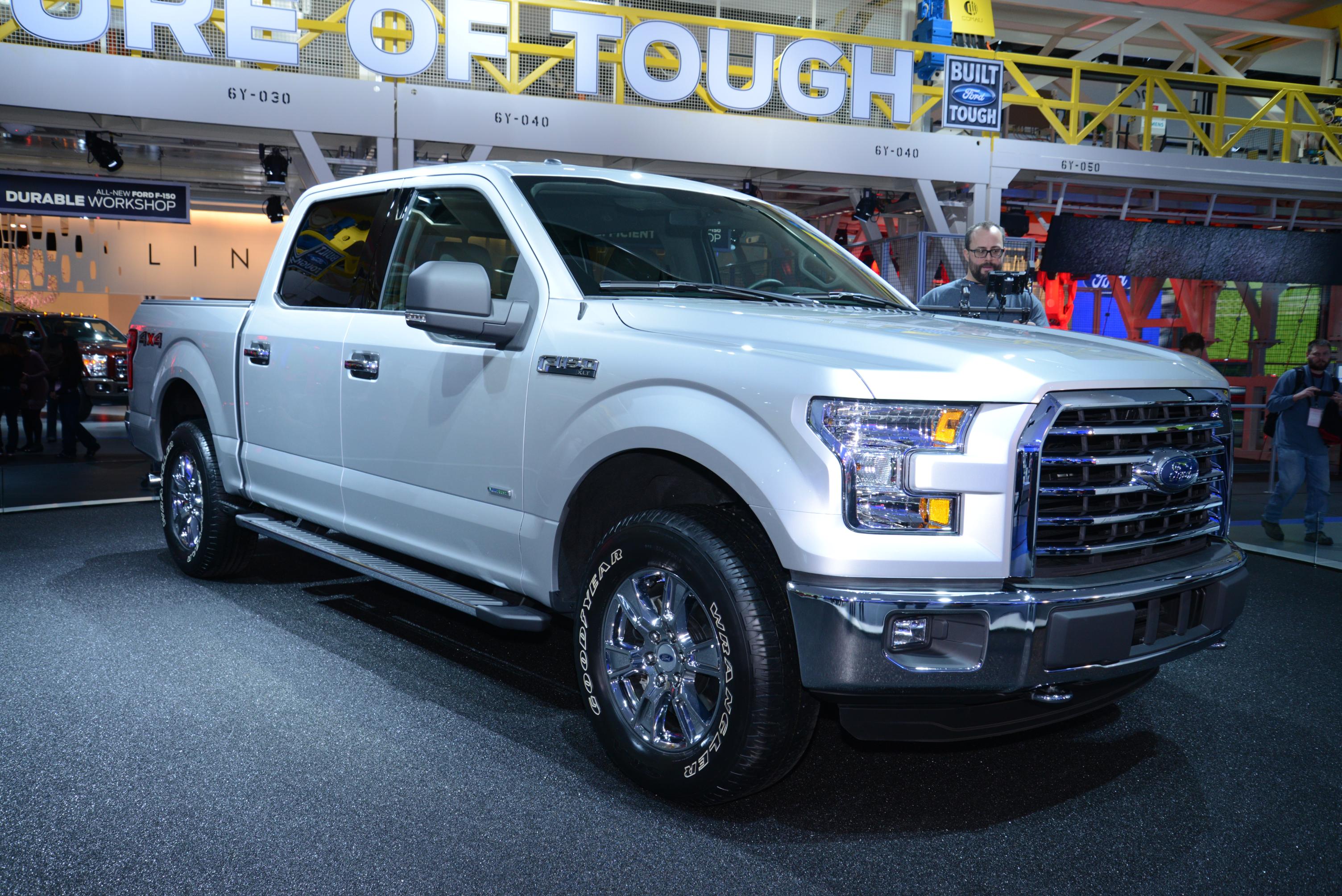

Both the exterior and interior design of Ford F-150 reflect decades of listening to customers and understanding their occupational and recreational needs. The exterior is characterized by a new shape that suggests capability, with a wider Built Ford Tough stance, prominent wheel arches and chiseled grille.

Comfort, utility and refinement define the truck’s interior. Ergonomically optimized seating for the front row positions enhances comfort, while extending legroom for rear passengers. Buttons and controls are optimized so they can be operated while wearing work gloves.

Storage options include laptop stowage in the center console, as well as quick storage solutions for cellphones, drinks, pens and business cards.

“Once again, the Ford F-150 establishes new standards in durability, capability, technology and efficiency to help F-150 owners be more productive 24/7 – whether for work or weekend fun,” said Nair.

The F-150 will continue to be manufactured at Ford’s Dearborn Truck Plant in Dearborn, Mich., and Kansas City Assembly Plant in Claycomo, Mo.

- Dealers and consumers across the United States start testing the all-new 2015 Ford F-150 ahead of its arrival in dealerships later this year

- All-new F-150 delivers industry’s best towing and payload capability among full-size pickups; F-150 can tow 12,200 pounds and haul 3,300 pounds

Regardless of model configuration or engine choice, every truck customer benefits from up to 700 pounds of weight savings with the 2015 F-150; F-150 can tow up to 1,100 more pounds, haul up to 530 more pounds and is projected to deliver fuel economy ratings in the range of at least 5 percent and as much as 20 percent higher gas mileage than today’s truck, depending on the model

The 2015 Ford F-150 – the reinvention of America’s favorite pickup – is winning early praise as it sets the standard for the future of tough, thanks to the all-new vehicle’s impressive combination of power, capability and efficiency.

This month, the first of 10,000 dealer sales consultants began test driving the new truck in 26 cities nationwide. Performance driving and competitive towing exercises are underscoring the industry’s best towing and payload capability among full-size pickups – the all-new F-150 can tow 12,200 pounds and haul 3,300 pounds.

Overall, the 2015 F-150 is the toughest, smartest, most capable F-150 ever. Regardless of model configuration or engine choice, every truck customer benefits from up to 700 pounds of weight savings the new truck delivers. The all-new F-150 can tow up to 1,100 more pounds, haul up to 530 more pounds and is projected to have fuel economy ratings in the range of at least 5 percent and as much as 20 percent better gas mileage than today’s truck, depending on the model. (Specific gas mileage numbers for the entire lineup will be certified by the U.S. EPA, likely in November, and announced at that time.)

Early test drives offered

Through December, dealer sales consultants will put the all-new F-150 through its paces in 26 cities, testing the truck’s speed and towing capability while experiencing its smart new features.

These early drives are meant to help sales professionals understand the truck’s strengths from the best perspective – the driver’s seat.

Consumers also can test drive the all-new F-150 ahead of the truck’s arrival in dealer showrooms. From Oct. 11 to Dec. 21, consumers in 38 U.S. cities can participate in up to 20,000 test drives of the new truck nationwide, with product experts along for the ride explaining smart new innovations and answering questions.

Consumers can preregister for events at F150drive.com. If no stops are yet planned near a customer’s location, he or she will be notified of future tour visits. Walk-up participation is encouraged.

Punishing testing proves toughest F-150 ever

The new truck’s improved performance is enabled by reducing up to 700 pounds of weight through the use of high-strength steel in the frame and high-strength, military-grade, aluminum alloy in the body.

Before the new F-150 goes on sale, it will have been torture-tested for more than 10 million miles in a range of temperatures and terrain – in labs, at Ford proving grounds, in the hands of some of the most demanding truck customers and even in the grueling Baja 1000 off-road race.

New technologies mean smartest F-150 ever

Several groundbreaking features debut in the all-new F-150, including 11 available class-exclusives:

- 360-degree camera view uses exterior cameras to create a bird’s-eye view of the truck to help drivers park, maneuver in tight spots, and navigate narrow roads and trails

- Integrated loading ramps enable easy loading of ATVs, motorcycles and mowers

- BoxLink combines metal brackets and custom cleats to secure a variety of accessories in the cargo box – from ramps to storage bins to bed dividers

- LED headlamps; LED taillamps provide excellent nighttime visibility

- Trailer hitch assist adds a new rearview camera feature that incorporates a dynamic line based on steering wheel angle in the display to help customers line up their truck and trailer with no spotter or need to exit the vehicle

- Remote tailgate allows for tailgate to be locked, unlocked and released with the key fob

The all-new F-150 lineup includes four engine options for more power, and to meet most any customer need:

- 2.7-liter EcoBoost® V6 with standard Auto Start-Stop: New engine design produces 325 horsepower and 375 lb.-ft. of torque. The 2.7-liter EcoBoost 4×2 has a maximum payload rating of 2,250 pounds and maximum tow rating of 8,500 pounds – ideal for meeting mid-range capability requirements and the needs of more than 90 percent of light-duty truck customers

- 3.5-liter EcoBoost: This twin-turbo EcoBoost engine delivers V8-like 420 lb.-ft. of torque and 365 horsepower to enable towing of up to 12,200 pounds – more than enough to handle a fully loaded, three-horse trailer or large boat. It has earned an industry-leading maximum payload rating of 3,180 pounds

- 5.0-liter V8 with twin independent variable camshaft timing: Improved power and efficiency, delivering 385 horsepower and 387 lb.-ft. of torque. Smart engineering enhancements such as a new long-runner intake manifold, revised intake cam duration and new pulse-separated exhaust manifolds help raise towing capability by 1,100 pounds to a maximum 11,100 pounds, and payload to 3,300 pounds

- 3.5-liter V6 with twin independent variable camshaft timing: This engine produces 283 horsepower and 255 lb.-ft. of torque. It has a maximum payload of 1,910 pounds and maximum tow rating of 7,600 pounds – unsurpassed for standard V6 light-duty pickup trucks

ALL-NEW FORD F-150 2.7-LITER ECOBOOST V6 ENGINE DELIVERS V8 CAPABILITY AND PERFORMANCE

- Tougher, lighter 2015 Ford F-150 welcomes two new engines to its four-engine lineup, providing choices to meet almost any customer need – from hauling tools to towing trailers

- High-output 2.7-liter EcoBoost® with standard Auto Start-Stop broadens engine lineup by providing mid-range V8-like towing capability of 8,500 pounds, payload of 2,250 pounds, 325 horsepower, 375 lb.-ft. of torque

- Standard 3.5-liter V6 engine with twin independent variable camshaft timing delivers impressive power and efficiency with towing of 7,600 pounds that can’t be beat, 1,910 pounds of payload, 283 horsepower and 255 lb.-ft. of torque

- Use of high-strength steel and high-strength, military-grade, aluminum alloy plus smart engineering saves up to 700 pounds, improving power-to-weight ratio and allowing for gains in towing, performance and efficiency

With its new 2.7-liter EcoBoost® with standard Auto Start-Stop and new 3.5-liter V6 with twin independent variable camshaft timing, the 2015 Ford F-150 resets the bar in light-duty pickup truck performance, capability and efficiency.

“The 2015 F-150 is the most capable F-150 yet, while shedding up to 700 pounds,” said Bob Fascetti, vice president, Powertrain Engineering. “These two new V6 engines – the 2.7-liter turbocharged EcoBoost and normally aspirated 3.5-liter Ti-VCT – set a new standard for Ford for capability and efficiency.”

2.7-liter EcoBoost power

The high-output, twin-turbo 2.7-liter EcoBoost V6 features an entirely new design that delivers power and performance in a strong, smart package. The engine produces 325 horsepower and 375 lb.-ft. of torque – improving the power-to-weight ratio of the 2015 truck by 15 percent over the 2014 5.0-liter V8-equipped F-150 with similar torque output, thanks to vehicle light-weighting.

The 2.7-liter EcoBoost 4×2 has a maximum payload rating of 2,250 pounds and maximum tow rating of 8,500 pounds, ideal for meeting mid-range capability needs.

Boosting 2.7-liter EcoBoost fuel efficiency is the debut of standard Auto Start-Stop technology for F-150. This technology, specially tuned for truck customers, shuts off the engine when the vehicle is at a stop. When the brake is released, the engine restarts quickly. Auto Start-Stop helps reduce fuel consumption and emissions when the truck is stopped and the engine is off. The technology is off when towing or in four-wheel-drive mode.

The 2.7-liter EcoBoost engine also features Ford’s first use of a compacted graphite iron cylinder block in a gasoline engine, the same material used in Ford’s 6.7-liter Power Stroke® turbo diesel V8 in Super Duty trucks. The composite CGI/aluminum cylinder block saves weight while providing strength where it’s needed most for durability.

Advanced technology, power and efficiency combine to create an engine for F-150 that boasts more than twice the horsepower, torque and towing capability of the Toyota Tacoma midsize pickup truck with identical displacement 2.7-liter four-cylinder engine.

Ford testing shows the 2.7-liter EcoBoost also outperforming Ram 1500 3.0-liter V6 EcoDiesel and Chevrolet Silverado 1500 5.3-liter V8 while towing a 7,000-pound enclosed trailer up Davis Dam in Arizona. This is the same grade the Society of Automotive Engineers uses for its J2807 towing testing standards, which the 2015 Ford F-150 will follow.

| Engine | Horsepower | Torque (lb.-ft.) | Payload (lbs.) | Towing (lbs.) |

| 2015 Ford F-150 4×4 2.7-liter EcoBoost |

325 | 375 | 2,250 | 8,500 |

| 2014 Toyota Tacoma 4×4 2.7-liter four-cylinder |

159 | 180 | 1,335 | 3,500 |

| 2014 Chevrolet Silverado 1500 4×4 5.3-liter V8 |

355 | 383 | 2,007 | 11,200 |

| 2014 Ram 1500 4×4 3.0-liter V6 EcoDiesel |

240 | 420 | 1,620 | 9,050 |

3.5-liter V6 tuned for responsive power

Thanks to vehicle weight savings, the standard 3.5-liter V6 with Ti-VCT offers a 5 percent improvement in power-to-weight ratio over the larger 3.7-liter V6 in the 2014 F-150, with better fuel efficiency and performance.

The 3.5-liter V6 produces 283 horsepower and 255 lb.-ft. of torque. The engine has a maximum payload of 1,910 pounds and a maximum tow rating of 7,600 pounds – unsurpassed for standard V6 light-duty pickup trucks.

Designed for impressive power and durability, the 24-valve 3.5-liter V6 features a valvetrain with direct-acting polished mechanical buckets with twin independent variable camshaft timing for impressive torque across a wide rpm range. Six-bolt main bearing caps, a fully counterweighted forged steel crankshaft and cast exhaust manifolds are designed for heavy-duty operation.

Both the upper and lower intake manifolds of the 3.5-liter V6 are tuned for responsive power, and both the intake manifolds and cam covers are composite-formed to reduce weight. The die-cast aluminum cylinder block features bay-to-bay breathing to reduce internal pumping losses, while a deep-sump oil pan contributes to extended oil-change intervals.

Advanced materials save weight

Extensive research by Ford engineers led to the use of more advanced materials on the 2015 F-150 than found in previous trucks. Military-grade aluminum alloys make the new truck’s body lighter, stronger and more resistant to dents.

Overall, F-150 is up to 700 pounds lighter – helping the truck tow and haul more, accelerate and stop faster, and operate more efficiently than the previous F-150. High-strength steel in the frame and high-strength aluminum alloy throughout the body produce an inherently stiffer truck with greater dent and ding resistance. The aluminum upper body sits on a fully boxed ladder frame with more high-strength steel than ever to make it stronger yet lighter.

In addition to the new V6 engines, the all-new 2015 F-150 offers the proven 3.5-liter EcoBoost and the 5.0-liter V8 with Ti-VCT, providing a comprehensive, capable and efficient engine lineup to meet the specific needs of Ford truck customers.

2015 FORD F-150 SUPERCREW EARNS TOP CRASH RATINGS

- National Highway Traffic Safety Administration awards 2015 Ford F-150 SuperCrew with its five-star Overall Vehicle Score in New Car Assessment Program, the highest possible rating, making it the safest F-150 ever

- All-new F-150 safety features include an advanced restraint system with dual-stage airbags, Curve Control to help drivers stay on their intended path, and available inflatable rear safety belts in SuperCrew models – a segment-first innovation

- 2015 F-150 – the toughest, smartest, most capable and efficient F-150 ever – includes the highest EPA-estimated fuel economy ratings of any full-sized gasoline pickup on the market, plus best-in-class towing and payload ratings

The all-new Ford F-150 SuperCrew has earned the government’s highest possible crash safety rating – adding to the F-150’s strengths as the toughest, smartest, most capable F-150 ever.

Thanks to 31 new safety-related innovations developed by the Ford truck team, the 2015 F-150 SuperCrew has earned a five-star Overall Vehicle Score in the National Highway Traffic Safety Administration’s New Car Assessment Program.

“The five-star safety rating is a terrific example of One Ford collaboration and innovation,” said Raj Nair, Ford group vice president, Global Product Development. “Our truck team worked together for years to deliver this accomplishment, using an unprecedented combination of advanced materials throughout the all-new F-150. The 2015 model is engineered to be the safest F-150 ever, which matters to customers who depend on this truck to not only get the job done, but also get them safely home.”

F-150’s improved performance is enabled by up to a 700-pound weight savings through the use of high-strength steel in the frame; high-strength, military-grade, aluminum alloy in the body; and smart engineering.

A cross-functional group comprised of Ford truck product development veterans and researchers worked to precisely optimize vehicle weight savings and manufacturing design to deliver improved durability, capability, fuel economy and crashworthiness. The team created and patented new structures, materials and joining methods that were tested virtually with supercomputer simulations, then retested in Ford’s advanced laboratories to engineer the safest F-150 ever.

Supercomputers for safety

The F-150 team started engineering the truck with supercomputers before the first units were ever even crash-tested in a lab.

Engineers developed digital safety models with nearly 1.4 million separate elements to examine how even the smallest parts of the truck would perform in a crash situation.

Safety starts with the frame

Safety starts with the truck’s signature, fully boxed frame – the backbone of the all-new F-150.

Engineers added an extra crossmember and increased the use of high-strength steel to improve stiffness, durability and safety – while also helping reduce the frame’s weight by up to 60 pounds.

“The team had to invent new ways to manage crash energy, because advanced materials like high-strength steel behave differently,” said Matt Niesluchowski, Ford truck safety manager. “We found that changing certain shapes led to a weight reduction, while also improving crash performance.”

Safety engineers developed a patented 12-corner front crush horn to dissipate more energy in a front impact. The uniquely shaped structure helps manage crash forces so the frame buckles predictably to keep those forces away from occupants in the cabin. This is just one of the 31 new safety-related innovations the team developed to make the truck safer in the event of a crash.

Safety improvements to the aluminum-alloy body

Ford’s advanced research and safety teams worked together to engineer F-150’s high-strength, military-grade, aluminum-alloy body structure to manage what happens to the body in the event of a crash.

The truck’s cab features hydroformed roof rails that constitute a cage-like structure around the doors, extruded roof bows to provide lateral strength across the top of the cab, and extruded rocker rails near the bottom to reinforce lower body strength.

How various parts of the truck were joined also yielded safety improvements. In many cases, welding was not the most effective way to join parts, so the team developed and patented methods to connect parts using high-strength adhesives. This resulted in structural strength equal to or greater than traditional welds.

Additional safety features

New to F-150 is an advanced restraint system that includes an adaptive steering column that adjusts energy management depending on occupant size and safety belt usage. The system includes dual-stage airbags and side-curtain airbags.

The all-new F-150 offers the following safety features:

- Safety belt pretensioners added to the belt anchor side that further tighten the lap belt around front seat occupants, keeping them in a more secure spot early in the event of a crash

- Curve Control, a technology that will slow the vehicle when it senses the truck is going too fast for a particular curve

- Available inflatable rear safety belts for SuperCrew – a segment-first feature

Driver-assist features

The 2015 F-150 introduces all-new driver-assist and semi-autonomous technologies, including several class-exclusive features such as adaptive cruise control and active park assist.

Adaptive cruise control and collision warning with brake support use radar in the front of the truck to measure the distance and speed of vehicles ahead. Using this information, F-150 can automatically slow to keep a consistent following distance set by the driver. Collision warning triggers visual and audio alerts if the system detects the following distance is diminishing too quickly and a collision may occur. It also pre-charges the brakes if the driver needs to stop suddenly.

Active park assist uses two ultrasonic sensors and electric power-assisted steering to help drivers parallel park. The sensors measure the gap between two vehicles to determine if there is enough room for the truck. After confirming the F-150 can fit, active park assist automatically steers the truck into the space, while the driver operates the accelerator and brake pedals.

Lane-keeping system is designed to help prevent a driver from drifting out of the intended driving lane. The system detects the left- or right-hand road lane markings using a camera mounted between the windshield and interior rearview mirror. A warning vibration in the steering wheel is used to alert the driver that the vehicle is drifting out of the lines. Semi-autonomous lane-keeping aid then can provide steering torque to help guide the vehicle back into the lane if needed.

Toughest, smartest, most capable and efficient F-150 ever

F-150’s advanced materials and weight savings lead to customer benefits regardless of model configuration or engine choice. The innovative new truck can tow up to 1,100 more pounds and haul up to 530 more pounds than the 2014 model, and it has the highest EPA-estimated fuel economy ratings of any full-sized gasoline pickup on the market.

When equipped with the available 2.7-liter EcoBoost® engine, the all-new F-150 4×2 returns EPA-estimated fuel economy ratings of 19 mpg city, 26 mpg highway and 22 mpg combined. Actual mileage will vary.

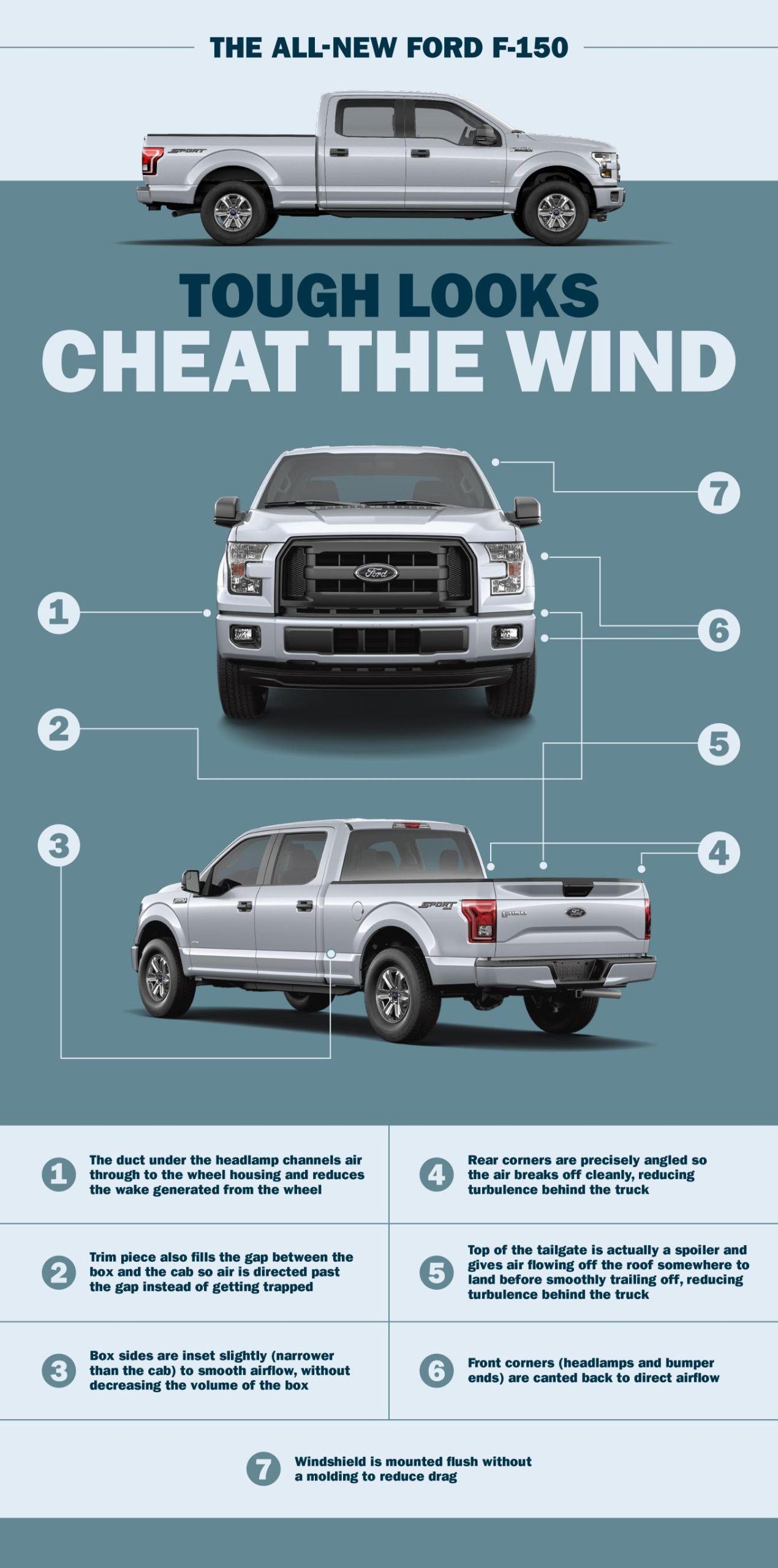

HOW FORD ENGINEERS MADE THE ALL-NEW F-150 THE TOUGHEST-LOOKING, MOST AERODYNAMICALLY EFFICIENT F-150 EVER

- Distinctive Built Ford Tough style of the all-new F-150 pushes boundaries of bold design while increasing aerodynamic efficiency over the previous model

- F-150 evolves hallmark design cues from first F-Series trucks

- Restyled badge echoes design elements throughout

Designers of the 2015 Ford F-150 had a challenging goal to meet when they set out to reimagine the world’s best-selling pickup: Create an aerodynamic, efficient design that did not compromise the tough, bold looks that define Ford trucks.

The team succeeded.

The new F-150’s structured look features squared-off edges, shapes and surfaces that convey confidence, capability and work readiness. Yet these elements also work together to allow F-150 to slip through the air more efficiently.

“The truck’s sharp, boxy shape gives it a tough appearance, but actually the key to the design is aerodynamic efficiency – getting the most out of the shape,” said Brad Richards, Ford F-150 exterior design manager. “We made F-150 look tough and capable, while also reducing wind resistance.”

Aerodynamic testing ensures a happy medium

Richards and team accomplished the feat of balancing strength and efficiency by incorporating sharp edges into the overall design. The strategically designed edges convey toughness, but also enable airflow to hug the surfaces at the front portion of the truck. Rear corners are designed to allow the air to cleanly detach from the vehicle to reduce turbulence and swirling air that can cause drag and reduce efficiency. The improved aerodynamics help increase efficiency by reducing the work performed by the engine to overcome aerodynamic drag.

The grille is vertical, yet its outer portions are angled back and lead to the headlamps and bumper corners that are also swept back to smoothly direct airflow down the sides, reducing drag. The beveled leading edge of the hood helps promote smooth airflow to the windshield and roof.

As the design of the all-new F-150 evolved with clay models, wind tunnel testing enabled designers to see where they could gain greater aerodynamic efficiencies:

- Flush-mounted windshield eliminates need for molding that would disrupt smooth airflow

- Tailgate top is designed to act as a spoiler, giving air that flows off the roof a place to land before smoothly trailing off, reducing turbulence behind the truck

- Cargo box is narrower than the cab, with no reduction in box volume, which enhances airflow, while a trim piece prevents air from getting trapped between cab and box

- Rear corners including taillamps are precisely angled so air breaks off cleanly, reducing turbulence behind the truck

- The duct under the headlamp channels air through to the wheel housing and reduces the wake generated from the wheel.

“Testing in the wind tunnel helped us fine-tune a happy medium between styling, aerodynamics, engineering and cost,” said Richards. “We learned where we could push shape and design to reduce drag, and where to stop when we weren’t gaining anything.”

Toughness is in the details

“The shapes, lines, angles and motifs are much stronger on the all-new F-150, and the chiseled edges convey toughness,” said Richards. “The hallmark beltline along the outside mirrors is the strongest piece of Built Ford Tough DNA. That’s inspired by heavy equipment such as cranes and bulldozers. It looks good, but it also improves driver visibility.”

The dropped beltline styling element can be seen in the outline of the headlamps and taillamps, while bevels, angles and notches are incorporated into the hood, windshield and tailgate, as well as throughout the interior, including the sew patterns on the seats.

F-150 also retains heritage design cues, such as the familiar headlamp shape that evokes the grille surround of the 1948 Ford F-1 and wraparound steel front bumper.

New badge signifies efficiency, leadership

Design details of the truck carry over to the new badge design, in which the characters are shaped with bevels to mimic those found in the body design.

The signature “F” has been opened up to signify a lighter, more efficient truck, yet it’s also larger to emphasize F-Series truck leadership.

The new badge design, using a font called Bold Leadership, will eventually find its way onto all F-Series trucks – right on through to the medium-duty Ford F-750.

“F-Series is all about bold and tough,” said Marco Querciagrossa, who leads badge design for Ford vehicles. “We created a badge that confidently conveys that.”

FORD ENGINEERS DESIGNED THE ALL-NEW F-150 TO RESIST FADING, DAMAGE AND GLARE FROM THE SUN

- Ford specially developed parts and extensively tested the 2015 Ford F-150 to resist fading and damage from harsh sunlight

- F-150 interior designed with brims and brows to minimize glare and shield gauges in the instrument panel while adding lighting to see recessed items

- Advanced computer modeling and testing in Ford’s Lighting Lab helped ensure sunlight reflecting off interior surfaces will not wash out gauge and screen displays

Sunlight takes a toll on a vehicle, much like it does your skin and eyes. So Ford designed and tested its all-new F-150 pickup to ensure a fade-resistant exterior and interior and to minimize interior glare.

Much of the testing was done in the company’s Central Lab, where Ford engineers focus on making individual parts stronger and more durable. A device known as a ‘Thermatron’ simulates damaging UV sun rays and can be used over long periods of time on prototype parts to help identify the best design for production.

Anti-glare testing took place in Ford’s Visual Performance Evaluation Lab, also known as the Lighting Lab. The Lighting Lab can replicate almost any sunlight conditions from dawn to dusk, as well as changes to natural light caused by weather conditions.

“‘Built Ford Tough’ means more than surviving dirt, rocks and mud or towing heavy trailers,” said Cindy McComb, Materials Engineer, Central Lab. “Ford trucks need to look as good after five years of exposure to sun, wind and rain as they do when they leave the showroom floor. Testing these conditions for long term durability is our job in Central Lab.”

Even the F-150’s badge is tough tested. Both the iconic Blue Oval and F-150 badges endured 3,000 hours of sun-like conditions — the equivalent of five years. The three-piece badge also was exposed to temperatures as cold as 40 below Celsius followed by blasts of steam as hot as 100 degrees Celsius to help ensure chrome plating adheres to the badge so individual pieces won’t warp or crack.

The Central Lab also places individual exterior and interior parts on outside racks for six months at a time at a facility in central Florida – NASA also conducts tests there – to look for fading and other signs of degradation. The parts were examined under a special xenon light to reveal damage normally invisible to the human eye. Parts are only approved for production if they meet rigorous fade-resistance standards.

Direct sunlight does more than fade parts over time. It can also make it hard to see information displayed on gauges and display screens used in navigation and entertainment systems. The new F-150 instrument panel has shaded gauges to minimize glare. Ford engineers also used advanced computer aided design software to identify the least reflective materials for use throughout the Ford F-150 interior.

Certain gauges and instruments shaded from glare are enhanced with supplemental lighting to make them readable in their recessed positions.

Indirect glare from general daylight brightness can wash out navigation and entertainment screen displays, too. Engineers tested various colors for the new F-150, ultimately choosing those that are easy to see under bright conditions.

“By reducing indirect glare, the driver should almost never see a sun spot in the center screen or instrument cluster,” said Cary Diehl, human factors engineer at Ford. “In addition to testing gauges and screens under these conditions, we even looked at the amount of light given off by LEDs in secondary controls such as window and steering wheel switches, to ensure they would not be distracting to the driver when lit.”

During anti-glare testing in the Lighting Lab, which boasts 6,000 watts of lighting and a planetarium-like dome, Ford tested prototype F-150s under a full variety of simulated lighting conditions.

“Many F-150 customers will use their truck for work at outdoor jobsites. They don’t have the time or patience to deal with hard to read gauges or controls inside the truck,” said Mahendra Dassanayake, Ford lighting technical specialist. “Our work in the Lighting Lab ensures that despite almost any weather outside, customers will find it easy to read controls inside the truck today and years from tomorrow.”

ALL-NEW FORD F-150 BOXLINK, LED BOX LIGHTS AND REMOTE TAILGATE RELEASE REVOLUTIONIZE TRUCK BED CARGO MANAGEMENT

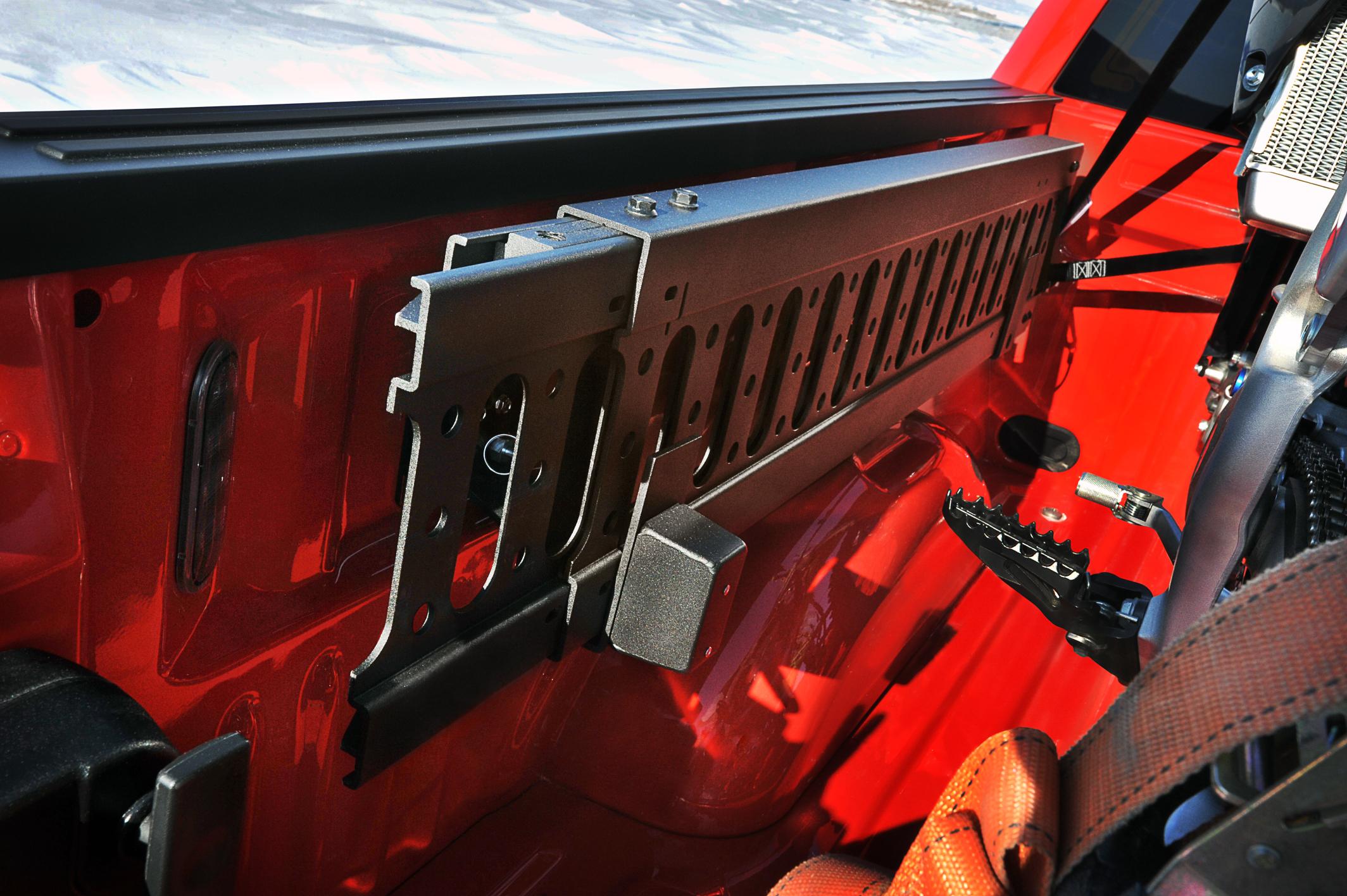

- Debuting in the all-new 2015 Ford F-150, class-exclusive BoxLink™ cargo management system includes lockable, die-cast zinc tie-down cleats, and provides a unique interface to the pickup bed for improved flexibility and organization, as well as additional locations for tie-downs

- All-new F-150 offers first LED box lights on a Ford truck, plus the availability of two segment-first features – power locking remote tailgate release and cargo ramps

- Ramps can be stowed on the sides of the pickup box via the BoxLink system and mounted quickly on the tailgate to enable easy loading of ATVs, motorcycles and mowers

From the days of horse-drawn carts, humans have used square-shaped boxes to move cargo.

Now, Ford is revolutionizing the management and stowage of cargo inside the pickup truck box with its patented BoxLink™ system debuting on the all-new Ford F-150. Along with LED box lights, a power locking and remote tailgate release, and segment-first cargo ramps, the 2015 F-150 is better equipped to help manage loads more efficiently.

BoxLink includes four lockable, die-cast zinc tie-down cleats, and provides a unique interface to the box for improved flexibility and organization, as well as additional locations for tie-downs.

“Rooted in the shape of the horse-drawn cart, the pickup truck box has been a standard, relatively unchanged fixture for nearly a century,” said Alana Strager, Ford program management analyst and co-inventor of the BoxLink system. “The industry’s acceptance of this shape meant the innovations we developed couldn’t alter the box, but rather needed to enhance and evolve its flexibility and modularity to create infinitely customizable solutions for hauling cargo.”

Perfecting the box

The BoxLink cargo management system allows for the customization of the pickup truck bed. A customer can attach to the BoxLink cleats in four locations, or hook directly to the BoxLink Interface plate with a bungee cord, S-hook or E-track fitting.

“Customers told us not to touch the box,” said Adrian Aguirre, Ford engineer and co-inventor of BoxLink. “They want to tailor it to their unique needs, and this system allows for easy adaptation to a variety of applications.”

BoxLink adds four additional tie-down locations in the box to complement the four fixed tie-down hooks carried over from the previous model, for a total of eight. Additionally, BoxLink is located on a reinforced area of the box at mid-level – accommodating the majority of cargo loads. Reinforcement of the cleats allows them to accommodate a horizontal (cross-box) load of 275 pounds and a diagonal load of 600 pounds.

Available segment-first cargo ramps can be stowed on the sides of the pickup box via the BoxLink system and mounted quickly on the tailgate to enable easy loading of ATVs, motorcycles and mowers. The length of telescoping ramps can be extended or shortened to accommodate multiple loading positions.

An altogether better box

The all-new F-150’s cargo box features many other significant upgrades to make it more versatile and driver-friendly.

LED cargo box interior lighting allows for excellent visibility in the truck bed at night or when a bed cover or cap is used. A bed-mounted button, as well as one inside the cab, turns the lights on or off. Lariat Mid or Luxury, King Ranch and Platinum models feature a remote tailgate release that includes an LED spotlight integrated into the release handle that illuminates the trailer hitch – a much appreciated convenience when hooking up after dark.

An available power locking and remote tailgate can be released with the push of a button on the key fob to help customers when their hands are full – a first for a pickup. The tailgate is damped and drops down, hands-free, to a flat position when opened.

2015 F-150 XLT models and higher benefit from a power locking tailgate for improved security. The feature is available for XL series trucks as well.

Ford’s pioneering tailgate step has been redesigned to be fully integrated into the tailgate and virtually invisible when not in use – restoring the open tailgate as a flat work surface. Using the step is simple: Customers drop the tailgate into the down position, grab the bottom step, pull it straight out from the tailgate and drop it down into the step position – all in one easy motion. The grab handle is now housed inside the tailgate, keeping the inner surface of the tailgate uniformly flat.

BoxLink designed for endless customization

Ford is allowing aftermarket manufacturers to leverage its BoxLink system to develop even more customized solutions for the pickup truck bed.

“This is an open system,” explained Strager. “We have facilitated the aftermarket in a way that has never been done before by an automaker. The possibilities are endless.”

ALL-NEW 2015 F-150 MOST PATENTED TRUCK IN FORD HISTORY – NEW INNOVATIONS BOLSTER NEXT-GENERATION LIGHT-DUTY PICKUP

- 2015 Ford F-150 has more new Ford technology patents and/or patent applications than any truck in Ford history, offering customers innovative technologies throughout – everything from the tailgate to the front end

- All-new F-150 boasts more than 100 new Ford patents and/or patent applications, making this vehicle a benchmark for new technologies in Ford’s storied history of truck leadership

- A Ford-developed heat treatment method for aluminum alloy nearly doubles the strength of the material, helping achieve better dent and ding resistance while reducing weight

From its tailgate step to the LED spotlights found on the side mirrors, the next-generation 2015 Ford F-150’s new features and technologies make it the most patented truck in company history.

“The all-new F-150 is loaded with innovation,” said Alana Strager, Ford program analyst charged with tracking new innovations for the 2015 truck. “Ford engineers filed more than 100 new patents for technologies on this truck as they have worked to redefine the light-duty pickup for the next generation.”

Patents and patent applications abound for state-of-the-art technologies covering new features and breakthroughs that will benefit customers of the all-new 2015 F-150. The scope of these innovations includes every part of the truck – body, exterior, interior, chassis, design, electrical and engine – as well as its manufacturing processes.

Patenting a smarter truck

Examples of Ford’s state-of-the-art technologies on the new 2015 F-150 include segment-exclusive LED spotlights found on the side mirrors, innovative remote tailgate release and smart trailer tow features that make towing easier.

- Innovative LED side-mirror spotlights allow customers to illuminate the side of the vehicle for tasks from setting up a campsite to changing a tire

- Remote tailgate release automatically lowers the tailgate with the push of a button on the key fob – a first for a pickup truck

- Ford’s pioneering tailgate step has been completely reengineered so it fully integrates into the tailgate, making it virtually invisible when not in use. The tailgate drops down into position in one easy motion. The grab handle is now housed inside the tailgate, which keeps the inner surface of the tailgate uniformly flat

- BoxLink™ cargo management system includes lockable, die-cast aluminum tie-down cleats, and provides a unique interface to the box for improved flexibility and organization, as well as additional locations for tie-downs. Available segment-first cargo ramps can be stowed on the sides of the pickup box via the BoxLink system and mounted quickly on the tailgate to enable easy loading of ATVs, motorcycles or mowers

Other smart features never offered before on a Ford pickup include 360-degree camera view, integrated loading ramps stowed in the pickup bed, 400-watt power outlets inside the cab and LED headlights.

Patenting toughness

Mounted on an exceptionally strong and well-proven high-strength steel frame, the all-new Ford F-150 incorporates the latest high-strength, military-grade, aluminum alloys to form the body and cargo box.

The aluminum is heat-treated using a proprietary method developed by Ford engineers that nearly doubles the strength of the metal. Ford is first in the auto industry to use this methodology.

Additionally, Ford engineers have filed patent applications for spot welding methods, adhesives and hydroforming this first-of-its-kind truck.

“Ford is teaching the world how to build a next-generation truck, and the more than 100 patents filed by the F-150 team for technologies on the 2015 truck further proves these Ford engineers and designers lead the automotive industry in innovation,” said Strager.

WITH POWER AND EFFICIENCY, FORD F-150 LEADS LIGHT-DUTY PICKUP TRUCKS IN V6 SALES

- 57 percent of Ford F-150 buyers in January and February choose V6 engine option

- Since 2010, Ford accounts for 91 percent of industry’s growth in V6 truck sales

- Ford F-150 V6 sales represented 78 percent of all light-duty truck V6 sales in 2013

- The Ford 3.5-liter EcoBoost™ engine represents 46 percent of F-150 pickup truck sales in February and the 3.7-liter V6 represents 11 percent.

More than 57 percent of Ford Motor Company’s F-150 retail sales so far this year are powered by V6 engines – the highest six-cylinder engine mix in the industry since 1967 – and the company expects that trend to continue for the rest of the year.

V8 engines led truck sales for decades until recently. Over the last three years, retail registrations of light duty pickups powered by V6 engines grew more than 600 percent and F-150 was directly responsible for 91 percent of that growth, based on Ford analysis of Polk retail registration data. In 2013, Ford accounted for 78 percent of all V6-powered half-ton pickups, according to data from Polk, recently acquired by IHS.

February’s engine mix numbers come on the heels of a very strong demand for Ford’s V6 truck engines in 2013. Of all the trucks Ford sold in the calendar year, more than 48 percent of them were powered by a V6 engine.

“We expect those numbers to hold for the rest of the year,” said Doug Scott, Ford Truck marketing manager. “It really is amazing when you consider we are doing that with just two V6 engine choices – the 3.5-liter V6 Ecoboost and the 3.7-liter Ti-VCT V6 engine. When we come out with the new 2015 F-150, we will offer three different V6 engines, so the potential is there to go even higher.”

The new 2015 Ford F-150 will offer a new 2.7-liter Ecoboost engine, to be made in Lima, Ohio, in addition to the 3.7-liter Ti-VCT V6 and 3.5-liter EcoBoost engines.

In the last three years, no competitor has ever eclipsed a 20 percent take rate for V6 engines in half-ton trucks. It’s been a predominantly V8 crowd, until the introduction of Ford’s EcoBoost engine.

“There is a new truck buyer out there who doesn’t hold to the old notion that a truck must be powered by a V8 engine,” Scott said. “Just five years ago, you would have had a hard time making a case for V6 truck engines. Not today. It’s all about fuel effectiveness. It’s the combination of city and highway mileage, horsepower, torque, towing capacity, payload and value. What is the most efficient package for the work I’m trying to do? That’s the key question.”

And it’s one F-150 truck buyers are answering in record numbers for V6 engines.