From “driving” to “gliding” in a hyper-agile and ultimately efficient EV that shifts the engineering paradigm to reveal a new dimension of driving fun and excitement

YOKOHAMA, Japan (Nov. 8, 2013) – More than a concept, Nissan BladeGlider is both a proposal for the future direction of Nissan electric vehicle (EV) development and an exploratory prototype of an upcoming production vehicle from the world’s leading EV manufacturer. BladeGlider was developed with form following function. Nissan crafted the vehicle’s unique architecture to give the driver and passengers “sustainable exhilaration” – a fresh electric vehicle driving experience based on peerless technology and exotic styling.

Targeting the visionary individual seeking visceral driving and sustainability, BladeGlider goes beyond sheer power and acceleration to send the heart soaring into new realms of smooth “gliding” pleasure. It is a physical demonstration of the innovation and excitement of the Nissan brand and Nissan’s Zero Emissions Mobility leadership. BladeGlider’s pioneering spirit distinguishes it from anything yet envisioned for EVs and destines it to rule the roads of the not-so-distant future.

Re-inventing the Performance Car – A Game Changer Designed from Scratch

A clean slate was the starting point for this project, led by Francois Bancon, division general manager of Product Strategy and Product Planning at Nissan. “The goal was to revolutionise the architecture of the vehicle to provoke new emotions, provide new value and make visible for consumers how Zero Emissions can help redefine our conception of vehicle basics,” said Bancon.

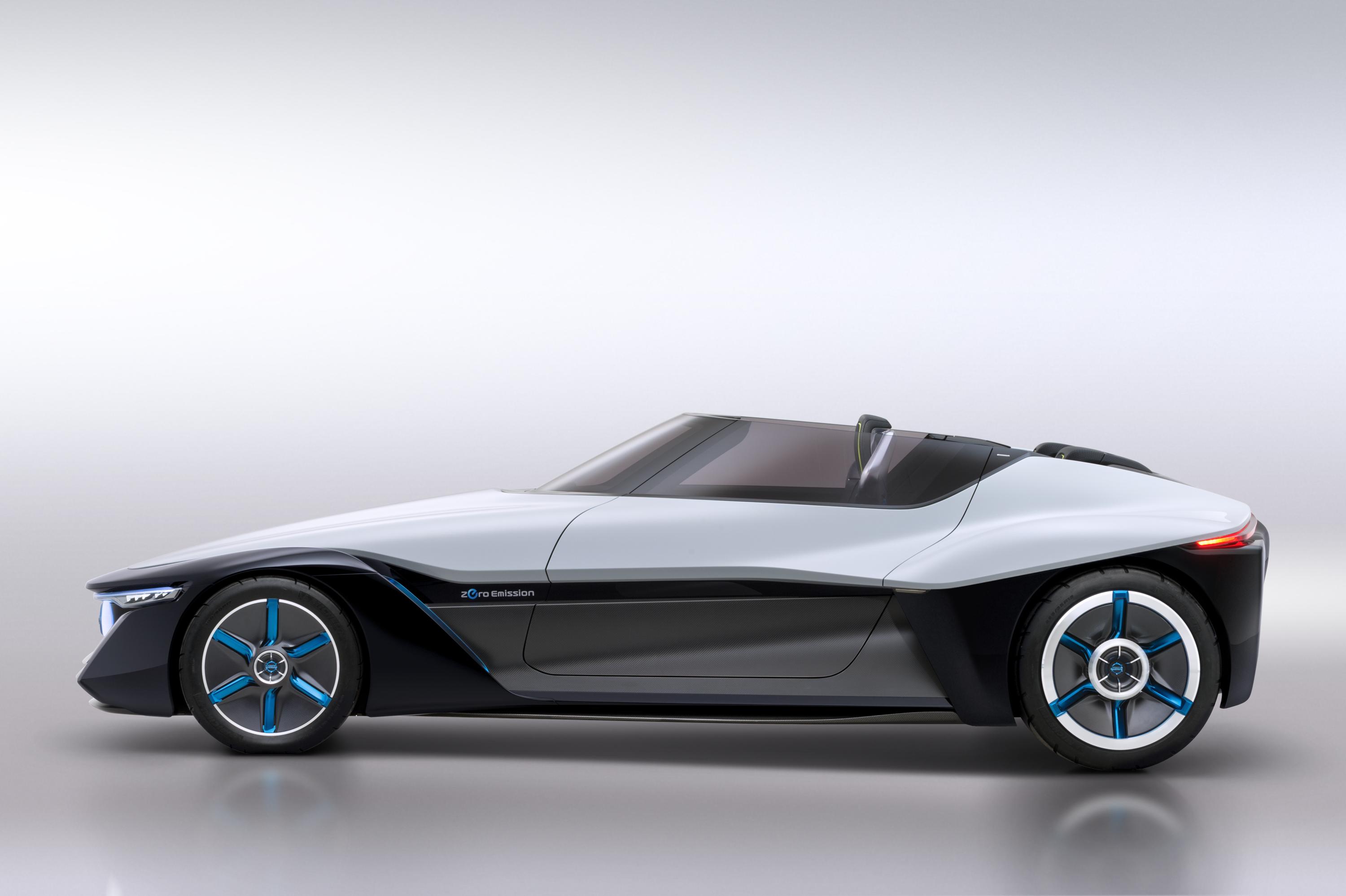

BladeGlider’s shape alone, with its narrow front track, challenges the orthodoxy that has dominated the roads since the earliest days of the internal combustion engine. The revolutionary nature of the car is more than skin deep. New possibilities for the designers and engineers were opened up by the unique characteristics of electric vehicles.

BladeGlider has its conceptual roots in two aerial images: the soaring, silent, panoramic freedom of a glider and the triangular shape of a high performance “swept wing” aircraft.

It is therefore fitting that, in terms of engineering, BladeGlider’s developmental focus was aerodynamics: achieving low drag (cdA) while generating road-hugging downforce.

Disruptive and challenging to the status quo, BladeGlider shares sustainable engineering values with both Nissan LEAF – the best-selling EV in history ─and the Nissan ZEOD RC (Zero Emission On Demand Racing Car), which will make its debut at next year’s Le Mans 24 Hour race.

A Provocative Shift in the Engineering Paradigm

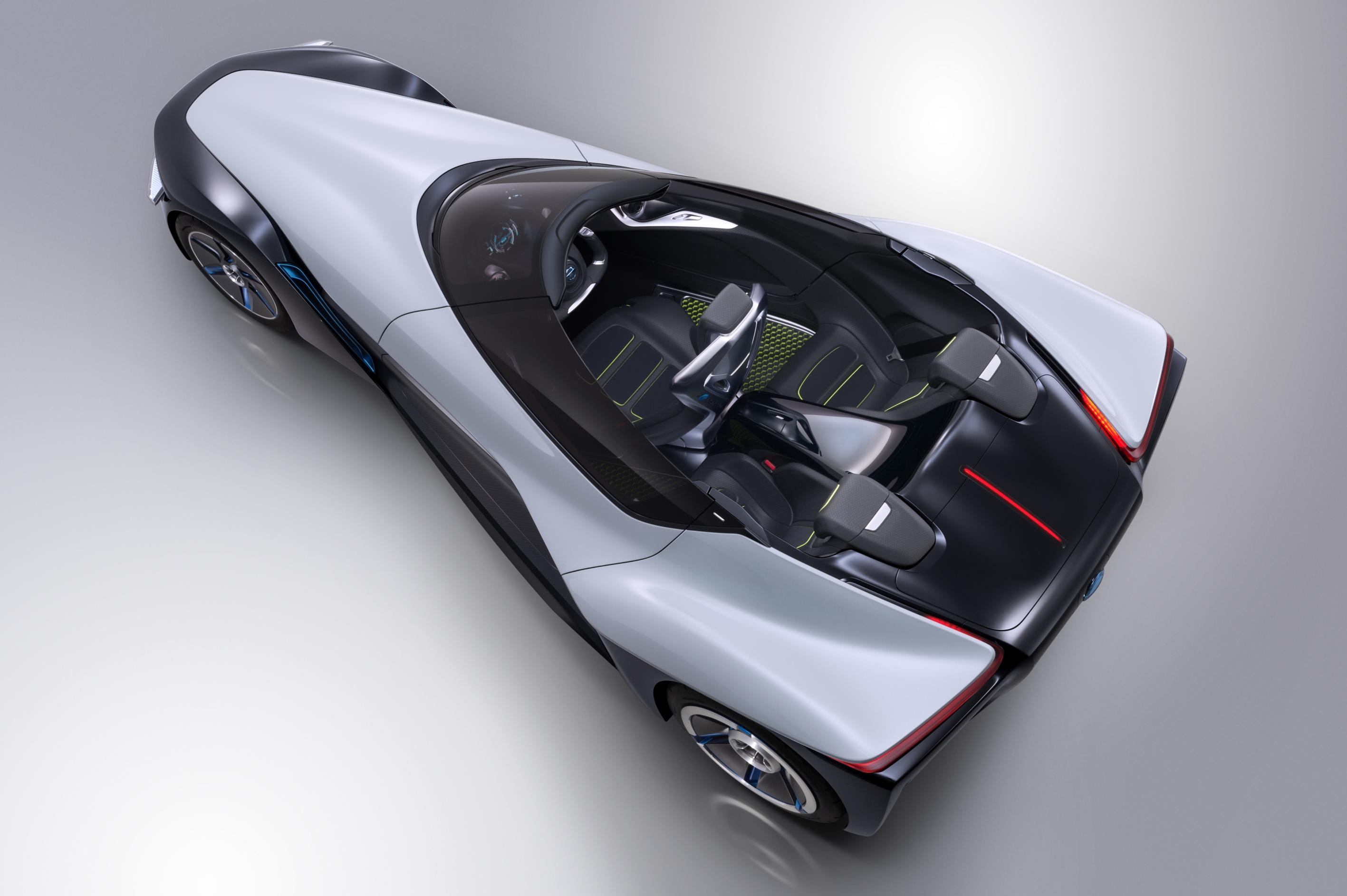

With its narrow, 1.0 metre lightweight front track and wide, stable rear track, BladeGlider looks as if it could have sprung from a “skunk works” project. But the radical architecture all boils down to aerodynamics and balance. Having the front wheels close together reduces drag and enhances manoeuvrability for high-G cornering power, assisted by its 30/70 front/rear weight distribution ratio. Aerodynamic downforce is created by the highly rigid yet lightweight carbon-fibre underbody, hence the lack of drag-inducing wings.

When BladeGlider matures into a production car, it could be Nissan’s first use of in-wheel motors. The in-wheel motors provide rear-wheel propulsion with independent motor management, while also contributing to freedom of upper body design and space-efficient packaging.

To power the electric motors, BladeGlider employs Nissan’s innovative lithium-ion battery technology, proven in Nissan LEAF. Battery modules are mounted low and towards the rear to enhance stability and handling.

Revolutionary Breakthrough in High-Performance Design

BladeGlider embodies a fearless vision of the EV future. Its tightly streamlined deltoid body comprises a tough and structurally optimised chassis wrapped in ultra-lightweight, yet strong and stiff, carbon fibre reinforced plastic (CFRP) finished in a pearlescent white colour that evokes the pristine freedom of a glider. The racing-inspired exterior features a sculpted contour that is both functional and breathtakingly beautiful. Starting from the low, flat and narrow nose, the body line rises gracefully to the cockpit canopy and then curves forcefully back over the large rear wheels, evoking a sense of dynamic movement even when the vehicle is standing still.

“BladeGlider was conceived around delivering a glider-like exhilaration that echoes its lightweight, downsized hyper-efficient aerodynamic form,” said Shiro Nakamura, Nissan’s senior vice president and chief creative officer. “This design is more than revolutionary; it’s transformational, applying our most advanced electric drive-train technology and racetrack-inspired styling in the service of a new dimension of shared driving pleasure.”

Inside the canopy, the cockpit seats three in a triangular configuration with the driver centre-forward. Seating appointments feature special light and comfortable coverings with yellow fluorescent lines. Amid simple yet edgy interior styling cues, an aircraft-type steering wheel and state-of-the-art instrumentation technology complete the glider-like image. To support maximum EV cruising efficiency, the IT system can display relief maps and atmospheric conditions.

“Free Soaring” Experience to be Shared with Friends

This efficient, aerodynamic, simple, and lightweight vehicle provides a “gliding” feel that combines the feeling of gravity-defying freedom and near-360 degree view of a glider with the pulse-quickening exhilaration of a race car.

“I think that the excitement of the racing car should be mirrored in the excitement of driving the road car,” said Ben Bowlby, director of Nissan Motorsport Innovation, who has supported the BladeGlider’s development. “I think there are elements we can bring from the race track to make these future road cars more exciting, more fulfilling and give greater driving pleasure.”

As a rear-drive performance car, BladeGlider exhibits a coherent and linear handling that enables it to consistently hug road curves, providing feedback for intuitive and exhilarating steering control when cornering under threshold conditions.

Augmenting BladeGlider’s aerodynamically-engineered precise feedback and control, the canopy-like visibility of the driving position engenders a synchronised feeling of oneness with the machine and the road. The result is a free soaring experience which the driver can share with two passengers in the V-shaped seating configuration. Passengers sit at the longitudinal centre of gravity to maintain the car’s balance at all times. The centre-driving setting of the cabin space is designed to enhance the driver’s sensatory experience.

As a final touch, the driver’s seat automatically slides laterally when you open the door, enabling easy access to passenger seats.

New EV Values for the Next Generation

By thinking outside the box, Nissan has created an EV that truly symbolises the unlimited potential of electric propulsion – balancing zero emissions with innovative excitement like never before.

THE SECRET BEHIND THE NISSAN BLADEGLIDER’S SUPERIOR PERFORMANCE

YOKOHAMA, Japan – Nissan unveiled its latest sports concept, the NISSAN BladeGlider, which will challenge conventional thinking on sports car performance handling, braking and weight distribution. The NISSAN BladeGlider features a radical front narrow track layout, where the front is significantly narrower than the rear, creating a swept-wing profile when seen from directly above the vehicle. This technology follows in the footsteps of Nissan’s ZEOD RC Zero Emission on Demand racecar (ZEOD RC), which will participate at next year’s Le Mans “Garage 56” event with the narrow front-track design. Director of Nissan Motorsport Innovation, Ben Bowlby, the designer of the ZEOD RC, also consulted during the development of the BladeGlider.

“When you see the narrow front track layout for the first time, everyone is skeptical on how the car will handle,” said Bowlby.” The concept has proved itself on the race track running as fast as the overall contenders. And I’m sure the BladeGlider will meet with the same initial skepticism, but we know, after extensive testing on the racetrack with race drivers behind the wheel, the Nissan BladeGlider has the potential to be the best handling production car in the world.”

Bowlby outlined the performance advantages of the BladeGlider’s narrow front-track/wide rear-track design.

Acceleration

The weight distribution of the BladeGlider makes it ideal for quick, efficient launches from a standstill and intense acceleration once off the line. The primary reason for this is that the rear tires are considerably wider than the front tires, resulting in more traction at the rear, enabling the tires to get a better grip on the driving surface. Also, the wide rear track allows for virtually all of the car’s heavier components—including the two in-board motors, lithium ion batteries and passengers—to sit between the rear tires; hence, most of the cars’ weight (70 percent in this case) sits directly on the two driven wheels. Therefore, when the power is sent to the rear wheels, the mid-engine/rear-drive BladeGlider exhibits very little tire slip, allowing the 285/35 tires to bite into the driving surface and launch the car in a highly efficient manner.

Thanks to the BladeGlider’s extremely narrow front end, which includes the skinny 100/80 tires, air drag is minimal. The BladeGlider features one of the lowest Cds ever for a concept road car, allowing the car to “glide” to speed with little air resistance.

Another benefit to the car’s narrow front end is weight. Thanks to less hardware and smaller components, the BladeGlider’s overall curb weight is considerably less than that of a similar size car with a conventional front end.

Handling

The most impressive, and most remarkable, advantage the BladeGlider has over its conventional counterparts is handling. While traditional performance enthusiast may scratch their respective heads wondering how a car with such a narrow front track can take corners; the answer is relatively simple. The narrow front track of the BladeGlider allows less weight to be placed on the front wheels. While some say that more weight on the front tires equals better grip, the complete opposite is actually true.

Sure, with super wide tires, extra load may result in more grip, but this is not an efficient solution, nor is it always true. For example, front-heavy cars are prone to excessive understeer – the loss of grip at the front wheels, where the car does not turn as much as the steering demands. The thinner tires up front allow the BladeGlider to turn in crisply because only 30 percent of the car’s total weight rests upon them. An added benefit is improved steering in terms of effort, feel and precision.

Also, the narrow front track allows the car to have minimal lateral weight transfer through corners, at both the front and rear ends. Cars with wider front tracks dramatically shift their weight to the outside tire when turning, leaving the inside tire to do virtually nothing. Thus, only one tire is steering the car through a corner; but with the BladeGlider, both tires stay in good contact with the road surface and share nearly the same cornering load, virtually working as one unit. And thanks to the independent suspension system, each tire’s effectiveness is augmented through turns.

The wide rear track and wide rear tires also contribute to the BladeGlider’s exceptional handling. By providing a stable and rigid foundation for the car, they allow the car’s front tires to effectively point the nose of the vehicle in the right direction. Think of a sledge hammer and its handle. Put the hammer on the ground and move the handle in the desired direction. It can be done with relatively little effort because the head of the hammer is providing a stable foundation. This unique effect of the BladeGlider can be enhanced with torque vectoring (or an enhanced limited slip differential) that can be programmed into the in-wheel motors, allowing the rear tires to help point the car’s nose.

Braking

Unlike conventional road vehicles, the rear brakes of the BladeGlider do more work than the front brakes when slowing the car down; therefore, they are larger and more powerful than the front brakes (the opposite is true in all other road cars). This provides a tremendous advantage when braking from high speed, as the wider tires, which have most of the car’s weight on them, provide excellent traction when decelerating. With the rear tires doing most of the work during acceleration and braking, and the front tires providing grip through turns, the overall performance workload at the four points of contact is distributed ideally: the front tires steer the car, the rear tires propel and stop the car.

X-Factor

With the driver sitting in the middle of the cockpit and near the rear wheels, the BladeGlider’s chassis relays clear and immediate feedback to the driver. Therefore, when the car’s front or rear tires lose grip, the chassis lets you know immediately, giving the driver ample time to correct car’s trajectory.

Another added benefit is tire wear, or lack thereof. Each rear tire and each front tire are doing an equal amount of work (as noted above), so their wear rate is also equal. Conventional cars frequently suffer from uneven tire wear, but the BladeGlider won’t require a tire change as often as a conventional car, especially when subjected to aggressive, spirited driving.