Determining the Age of a Tire

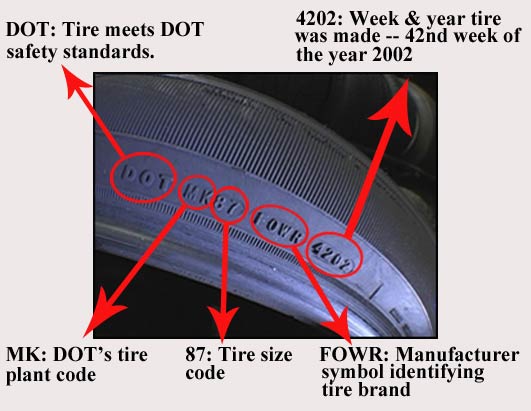

When it comes to determining the age of a tire, it is easy to identify when a tire was manufactured by reading its Tire Identification Number (often referred to as the tire’s serial number). Unlike vehicle identification numbers (VINs) and the serial numbers used on many other consumer goods (which identify one specific item), Tire Identification Numbers are really batch codes that identify the week and year the tire was produced.

The U.S. Department of Transportation (DOT) National Highway Traffic Safety Administration (NHTSA) requires that Tire Identification Numbers be a combination of the letters DOT, followed by ten, eleven or twelve letters and/or numbers that identify the manufacturing location, tire size and manufacturer’s code, along with the week and year the tire was manufactured.

Tires Manufactured Since 2000

Since 2000, the week and year the tire was produced has been provided by the last four digits of the Tire Identification Number with the 2 digits being used to identify the week immediately preceding the 2 digits used to identify the year.

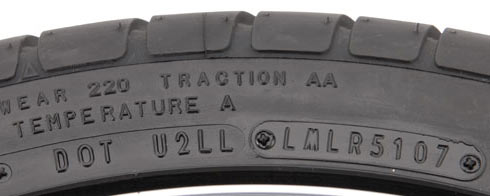

Example of a tire manufactured since 2000 with the current Tire Identification Number format:

In the example above: DOT U2LL LMLR 5107

DOT U2LL LMLR 5107 Manufactured during the 51st week of the year

DOT U2LL LMLR 5107 Manufactured during 2007

While the entire Tire Identification Number is required to be branded onto one sidewall of every tire, current regulations also require that DOT and the first digits of the Tire Identification Number must also be branded onto the opposite sidewall. Therefore, it is possible to see a Tire Identification Number that appears incomplete and requires looking at the tire’s other sidewall to find the entire Tire Identification Number

The use of a partial Tire Identification Number on the one sidewall (shown above) reduces the risk of injury to the mold technician that would have to install the weekly date code on the top sidewall portion of a hot tire mold.

Tires Manufactured Before 2000

The Tire Identification Number for tires produced prior to 2000 was based on the assumption that tires would not be in service for ten years. While they were required to provided the same information as today’s tires, the week and year the tire was produced was contained in the last three digits. The 2 digits used to identify the week a tire was manufactured immediately preceded a single digit used to identify the year.

Example of a tire manufactured before 2000 with the earlier Tire Identification Number format:

In the example above: DOT EJ8J DFM 408

DOT EJ8J DFM 408 Manufactured during the 40th week of the year

DOT EJ8J DFM 408 Manufactured during the 8th year of the decade

While the previous Tire Identification Number format identified that a tire was built in the 8th year of a decade, there was no universal identifier that confirmed which decade (tires produced in the 1990s may have a small triangle following the Tire Identification Number to identify the decade).

And finally, hold on to your sales receipt. Most tire manufacturer’s warranties cover their tires for four years from the date of purchase or five years from the week the tires were manufactured. So if you purchase new tires that were manufactured exactly two years ago they will be covered for a total of six years (four years from the date of purchase) as long as you have your receipt. If you lose your receipt, your tires’ warranty coverage will end five years from the week the tire was produced (resulting in the tire manufacturer’s warranty coverage ending only three years from the date of purchase in this example).

Calculating Approximate Tire Dimensions

Most modern passenger car and light truck tires feature size designations that indicate the tire’s dimensions in a combination of metric, mathematical and English systems. While this unusual combination of millimeters, percentages and inches is a byproduct of the evolution of global tire specifications, it also provides the ability to calculate/estimate basic tire dimensions

Example size: 225/45R17

Example size: 225/45R17

The first three numbers in a typical size (225/45R17) are the tire’s indicated section width in millimeters, measured from sidewall to sidewall.

If you are familiar with measurements in inches, the section width in millimeters can be converted into inches by dividing it by 25.4. For example:

-

-

-

- 225mm / 25.4 = 8.86″

-

-

The second pair of numbers (225/45R17) is the tire’s aspect ratio or profile. This is a ratio of sidewall height to section width. The section height’s measurement can be calculated by multiplying the section width by the aspect ratio. The answer will be the height of one sidewall. For example:

-

-

-

- 225mm x 0.45 = 101.3mm

8.86″ x 0.45 = 3.99″

- 225mm x 0.45 = 101.3mm

-

-

The last number (225/45R17) is the diameter of the wheel in inches.

If you are familiar with measurements in the metric system, the wheel diameter can be converted into millimeters by multiplying it by 25.4. For example:

-

-

-

- 17″ x 25.4 = 431.8mm

-

-

To calculate the overall diameter of a tire, the sidewall height must be multiplied by 2 (remembering that the tire diameter is made up of 2 sidewalls, the one above the wheel and the one below the wheel touching the ground) and add the diameter of the wheel.

-

-

- 101.3mm + 101.3mm + 431.8mm = 634.4mm

3.99″ + 3.99″ + 17″ = 24.98″

- 101.3mm + 101.3mm + 431.8mm = 634.4mm

-

WARNING: These calculations (and those provided by all online tire dimension calculators) only reflect nominal tire dimensions, which are often subtly or substantially different than the tire’s actual physical size and/or the dimensions provided by the tire manufactures.

Drivers working with close fitment tolerances or trying to maintain the original tire diameter of staggered size fitments (similarities or differences) should use the tire manufacturer’s specifications for the exact tire(s) they are considering.

Actual Tire Section Width is Dependent on Wheel Width

All tire sizes are assigned specific rim widths upon which they are measured (measuring rim), as well as can often be mounted on slightly narrower or wider wheels (rim width range). Therefore, it is important to note that actual tire section width will depend on the wheel width the tire is mounted on. The rule of thumb is that tire section width changes by 0.2″ for every 0.5″ change in rim width, being reduced if mounted on narrower then measuring wheel and increased when mounted on wider wheels.

Tires Background

A tire is a strong, flexible rubber casing attached to the rim of a wheel. Tires provide a gripping surface for traction and serve as a cushion for the wheels of a moving vehicle. Tires are found on automobiles, trucks, buses, aircraft landing gear, tractors and other farm equipment, industrial vehicles such as forklifts, and common conveyances such as baby carriages, shopping carts, wheel chairs, bicycles, and motorcycles.

Tires for most vehicles are pneumatic; air is held under pressure inside the tire. Until recently, pneumatic tires had an inner tube to hold the air pressure, but now pneumatic tires are designed to form a pressure seal with the rim of the wheel.

Scottish inventor Robert Thomson developed the pneumatic tire with inner tube in 1845, but his design was ahead of its time and attracted little interest. The pneumatic tire was reinvented in the 1880s by another Scotsman, John Boyd Dunlop, and became immediately popular with bicyclists.

Natural rubber is the main raw material used in manufacturing tires, although synthetic rubber is also used. In order to develop the proper characteristics of strength, resiliency, and wear-resistance, however, the rubber must be treated with a variety of chemicals and then heated. American inventor Charles Goodyear discovered the process of strengthening rubber, known as vulcanization or curing, by accident in 1839. He had been experimenting with rubber since 1830 but had been unable to develop a suitable curing process. During an experiment with a mixture of india rubber and sulfur, Goodyear dropped the mixture on a hot stove. A chemical reaction took place and, instead of melting, the rubber-sulfur mixture formed a hard lump. He continued his experiments until he could treat continuous sheets of rubber.

Today, large, efficient factories staffed with skilled workers produce more than 250 million new tires a year. Although automation guides many of the steps in the manufacturing process, skilled workers are still required to assemble the components of a tire.

Raw Materials

Rubber is the main raw material used in manufacturing tires, and both natural and synthetic rubber are used. Natural rubber is found as a milky liquid in the bark of the rubber tree, Hevea Brasiliensis. To produce the raw rubber used in tire manufacturing, the liquid latex is mixed with acids that cause the rubber to solidify. Presses squeeze out excess water and form the rubber into sheets, and then the sheets are dried in tall smokehouses, pressed into enormous bales, and shipped to tire factories around the world. Synthetic rubber is produced from the polymers found in crude oil.

The other primary ingredient in tire rubber is carbon black. Carbon black is a fine, soft powder created when crude oil or natural gas is burned with a limited amount of oxygen, causing incomplete combustion and creating a large amount of fine soot. So much carbon black is required for manufacturing tires that rail cars transport it and huge silos store the carbon black at the tire factory until it is needed.

Sulfur and other chemicals are also used in tires. Specific chemicals, when mixed with rubber and then heated, produce specific tire characteristics such as high friction (but low mileage) for a racing tire or high mileage (but lower friction) for a passenger car tire. Some chemicals keep the rubber flexible while it is being shaped into a tire while other chemicals protect the rubber from the ultraviolet radiation in sunshine.

Design

The main features of a passenger car tire are the tread, the body with sidewalls, and the beads. The tread is the raised pattern in contact with the road. The body supports the tread and gives the tire its specific shape. The beads are rubber-covered, metal-wire bundles that hold the tire on the wheel.

Computer systems now play a major role in tire design. Complex analysis software acting on years of test data allows tire engineers to simulate the performance of tread design and other design parameters. The software creates a three-dimensional color image of a possible tire design and calculates the effects of different stresses on the proposed tire design. Computer simulations save money for tire manufacturers because many design limitations can be discovered before a proto-type tire is actually assembled and tested.

In addition to tests of tread design and tire body construction, computers can simulate the effects of different types of rubber compounds. In a modern passenger car tire, as many as twenty different types of rubber may be used in different parts of the tire. One rubber compound may be used in the tread for good traction in cold weather; another compound is used to give increased rigidity in the tire sidewalls.

After tire engineers are satisfied with computer studies of a new tire, manufacturing engineers and skilled tire assemblers work with the designers to produce tire prototypes for testing. When design and manufacturing engineers are satisfied with a new tire design, tire factories begin mass production of the new tire.

Tire construction. (a) Bias-ply. (b) Radial-ply. (c) Belted bias-ply.

(Goodyear Tire and Rubber Co.)

The Manufacturing Process

A passenger car tire is manufactured by wrapping multiple layers of specially formulated rubber around a metal drum in a tire-forming machine. The different components of the tire are carried to the forming machine, where a skilled assembler cuts and positions the strips to form the different parts of the tire, called a “green tire” at this point. When a green tire is finished, the metal drum collapses, allowing the tire assembler to remove the tire. The green tire is then taken to a mold for curing.

- The first step in the tire manufacturing process is the mixing of raw materials to form the rubber compound. Railcars deliver large quantities of natural and synthetic rubber, carbon black, sulfur, and other chemicals and oils, all of which are stored until needed. Computer control systems contain various recipes and can automatically measure out specific batches of rubber and chemicals for mixing. Gigantic mixers, hanging like vertical cement mixers, stir the rubber and chemicals together in batches weighing up to 1,100 pounds.

- Each mix is then remilled with additional heating to soften the batch and mix the chemicals. In a third step, the batch goes through a mixer again, where additional chemicals are added to form what is known as the final mix. During all three steps of mixing, heat and friction are applied to the batch to soften the rubber and evenly distribute the chemicals. The chemical composition of each batch depends on the tire part—certain rubber formulations are used for the body, other formulas for the beads, and others for the tread.

Body, beads, and tread

- Once a batch of rubber has been mixed, it goes through powerful rolling mills that squeeze the batch into thick sheets. These sheets are then used to make the specific parts of the tire. The tire body, for instance, consists of strips of cloth-like fabric that are covered with rubber. Each strip of rubberized fabric is used to form a layer called a ply in the tire body. A passenger car tire may have as many as four plies in the body.

- For the beads of a tire, wire bundles are formed on a wire wrapping machine. The bundles are then formed into rings, and the rings are covered with rubber.

- The rubber for the tire tread and sidewalls travels from the batch mixer to another type of processing machine called an extruder. In the extruder, the batch is further mixed and heated and is then forced out through a die—a shaped orifice—to form a layer of rubber. Sidewall rubber is covered with a protective plastic sheet and rolled. Tread rubber is sliced into strips and loaded into large, flat metal cases called books.

Tire-building machine - The rolls of sidewall rubber, the books containing tread rubber, and the racks of beads are all delivered to a skilled assembler at a tire-building machine. At the center of the machine is a collapsible rotating drum that holds the tire parts. The tire assembler starts building a tire by wrapping the rubber-covered fabric plies of the body around the machine drum. After the ends of these plies are joined with glue, the beads are added and locked into place with additional tire body plies laid over the beads. Next, the assembler uses special power tools to shape the edges of the tire plies. Finally, the extruded rubber layers for the sidewalls and tread are glued into place, and the assembled tire—the green tire—is removed from the tire-building machine.

Curing

- A green tire is placed inside a large mold for the curing process. A tire mold is shaped like a monstrous metal clam which opens to reveal a large, flexible balloon called a bladder. The green tire is placed over the bladder and, as the clamshell mold closes, the bladder fills with steam and expands to shape the tire and force the blank tread rubber against the raised interior of the mold. During this curing process, the steam heats the green tire up to 280 degrees. Time in the mold depends on the characteristics desired in the tire.

- After curing is complete, the tire is removed from the mold for cooling and then testing. Each tire is thoroughly inspected for flaws such as bubbles or voids in the rubber of the tread, sidewall, and interior of the tire. Then, the tire is placed on a test wheel, inflated, and spun. Sensors in the test wheel measure the balance of the tire and determine if the tire runs in a straight line. Because of the design and assembly of a modern tire, rarely is one rejected. Once the tire has been inspected and run on the test wheel, it is moved to a warehouse for distribution.

Quality Control

Quality control begins with the suppliers of the raw materials. Today, a tire manufacturer seeks suppliers who test the raw materials before they are delivered to the tire plant. A manufacturer will often enter into special purchasing agreements with a few suppliers who provide detailed certification of the properties and composition of the raw materials. To insure the certification of suppliers, tire company chemists make random tests of the raw materials as they are delivered.

Throughout the batch mixing process, samples of the rubber are drawn and tested to confirm different properties such as tensile strength and density. Each tire assembler is responsible for the tire components used. Code numbers and a comprehensive computer record-keeping system allow plant managers to trace batches of rubber and specific tire components.

When a new tire design is being manufactured for the first time, hundreds of tires are taken from the end of the assembly line for destructive testing. Some of the tires, for example, are sliced open to check for air pockets between body plies, while others are pressed down on metal studs to determine puncture resistance. Still other tires are spun rapidly and forced down onto metal drums to test mileage and other performance characteristics.

A variety of nondestructive evaluation techniques are also used in tire quality control. X-ray videography provides a quick and revealing view through a tire. In an X-ray tire test, a tire is selected at random and taken to a radiation booth where it is bombarded with X-rays. A test technician views the X-ray image on a video screen, where tire defects are easily spotted. If a defect shows up, manufacturing engineers review the specific steps of tire component assembly to determine how the flaw was formed.

In addition to internal testing, feedback from consumers and tire dealers is also correlated with the manufacturing process to identify process improvements.

STAY SAFE THIS WINTER WITH TYRESAFE’S ‘MAGNIFICENT 7’

- To help motorists stay safe and legal when driving this winter, TyreSafe has compiled its ‘Magnificent 7’ list of tyre safety tips.

While fitting winter tyres is one way to ensure greater driving safety when the temperature drops below 7 degrees Celsius, the other six pieces of winter advice needn’t cost a penny, although a 20p coin will certainly be useful!

Stuart Jackson, chairman, TyreSafe, explained: “This October’s Tyre Safety Month concentrates getting drivers ready for winter. While fitting winter weather tyres is an obvious and sensible option, there are plenty of other aspects of tyre maintenance that all drivers should be doing, regardless of whether they make the switch to winter rubber or not.

“Our ‘Magnificent 7’ has been compiled by industry experts who know what they’re talking about. If drivers follow our advice then they’ve got a much better chance of staying safe on the roads this winter.”

The advice from TyreSafe comes just days after the Department for Transport issued its latest road casualty report which showed that in 2010, there were more than 1,200 road casualties in the UK from tyre related accidents, emphasising the need for better tyre care.

TyreSafe’s tips include checking for adequate tread depth by taking the 20p test, ensuring tyres are properly inflated and inspecting the conditions of tyres by looking for any lumps, bulges and cracks. They also cover the spare tyre, removal or jacking of wheels on any vehicles that are not used in the winter months. For anyone confused by these or any other aspect of tyre safety, TyreSafe’s final piece of advice is to visit one of the many tyre dealers and garages who are offering free tyre safety checks as part of October’s tyre safety month.

“Seven is seen as a lucky number by many, but luck plays no part when it comes to tyre safety. Regular checks and maintenance are vital. However, if you’re at all unsure about any aspect regarding tyre safety, don’t leave it to chance. Call into your nearest dealer and get them checked out by an expert,” concludes Jackson.

TyreSafe’s ‘Magnificent 7’ tyre safety tips

- Make sure your tyres have adequate tread depth to keep you safe and legal by taking the 20p test

- Ensure your tyres are properly inflated and checked at least once a month and before any long journeys

- Check the condition of your tyres by looking for any lumps, bulges or cracks and remove any objects embedded in the tread

- When checking the tread, pressures and condition, don’t forget the spare

- Consider fitting winter weather tyres for the whole winter period. At temperatures below 7 degrees C they provide much better safety and grip

- Remove wheels or jack the weight off any vehicles’ tyres that will not be used over the winter months such as caravans, horseboxes or motorcycles

- Visit your nearest participating tyre dealer for a free tyre safety check

ALSO SEE

Click Image