A MOMENTOUS UNITY OF ART, TECHNOLOGY AND VELOCITY

- McLaren’s first ‘Hyper-GT’ and the ultimate McLaren road car; harmonizes sleek and seamless beauty with pioneering technologies and extreme performance

- A car like no other: only 106 will be produced, all of which are already reserved at a price from £1.75million plus taxes

- Carbon fibre McLaren Monocage body structure unique to the Speedtail envelops McLaren F1-inspired central driving position and two additional passenger seats

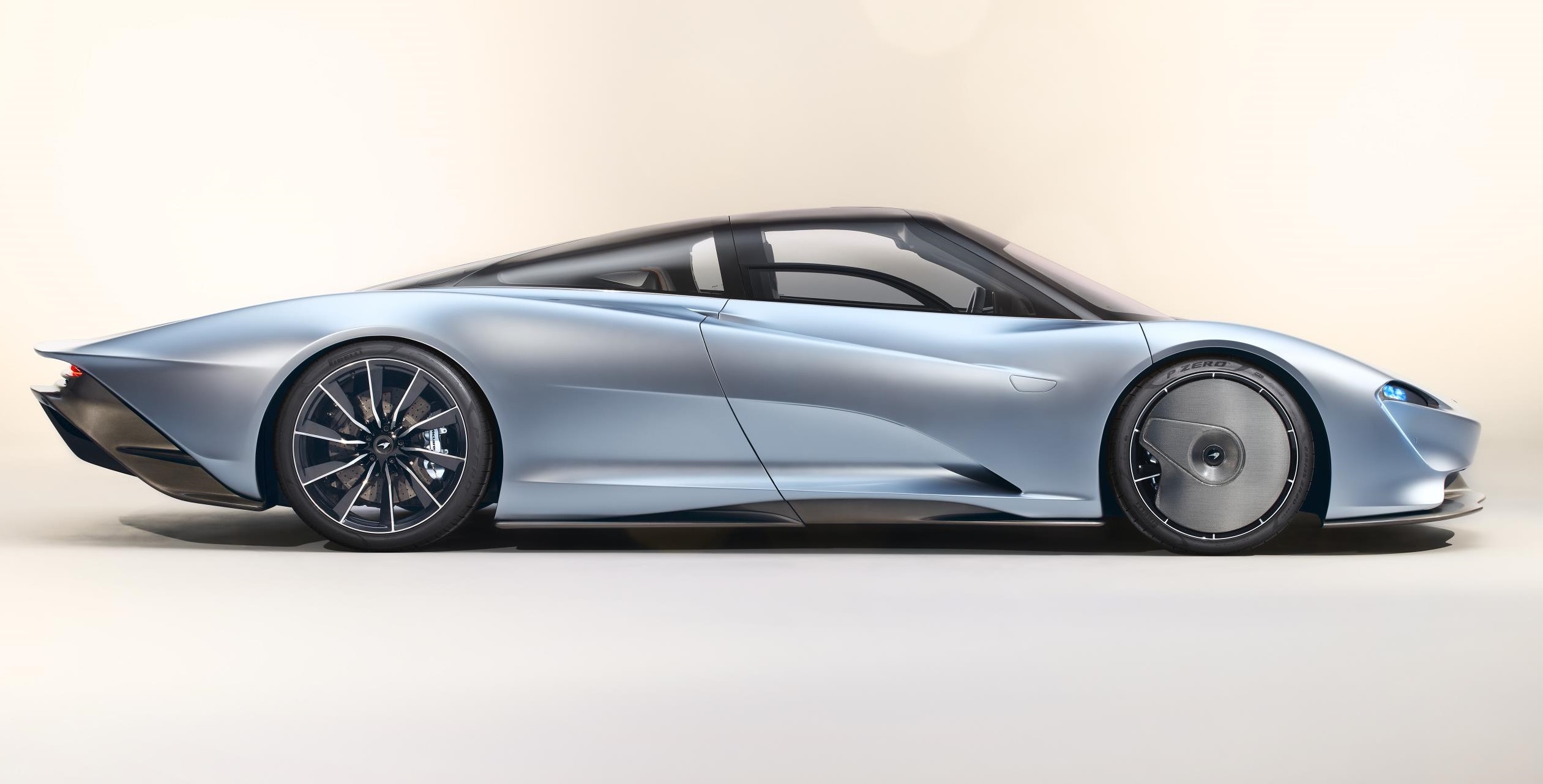

- Teardrop-shaped cockpit and dramatically elongated, aerodynamically optimized, 16.9ft (5,137mm) carbon fiber body key to Speedtail being the most aero-drag efficient McLaren road car

- The fastest McLaren ever built, capable of 250mph (403km/h)

- Pioneering petrol-electric hybrid powertrain delivers a combined 1,035bhp (1,050PS) for acceleration of 0-186mph in 12.8 seconds

- Unique Velocity mode optimizes the powertrain and active aerodynamics to achieve maximum speed and can also lower the Speedtail by 1.4in (35mm)

- Bespoke P-ZERO™ tyre developed with McLaren technology partner, Pirelli

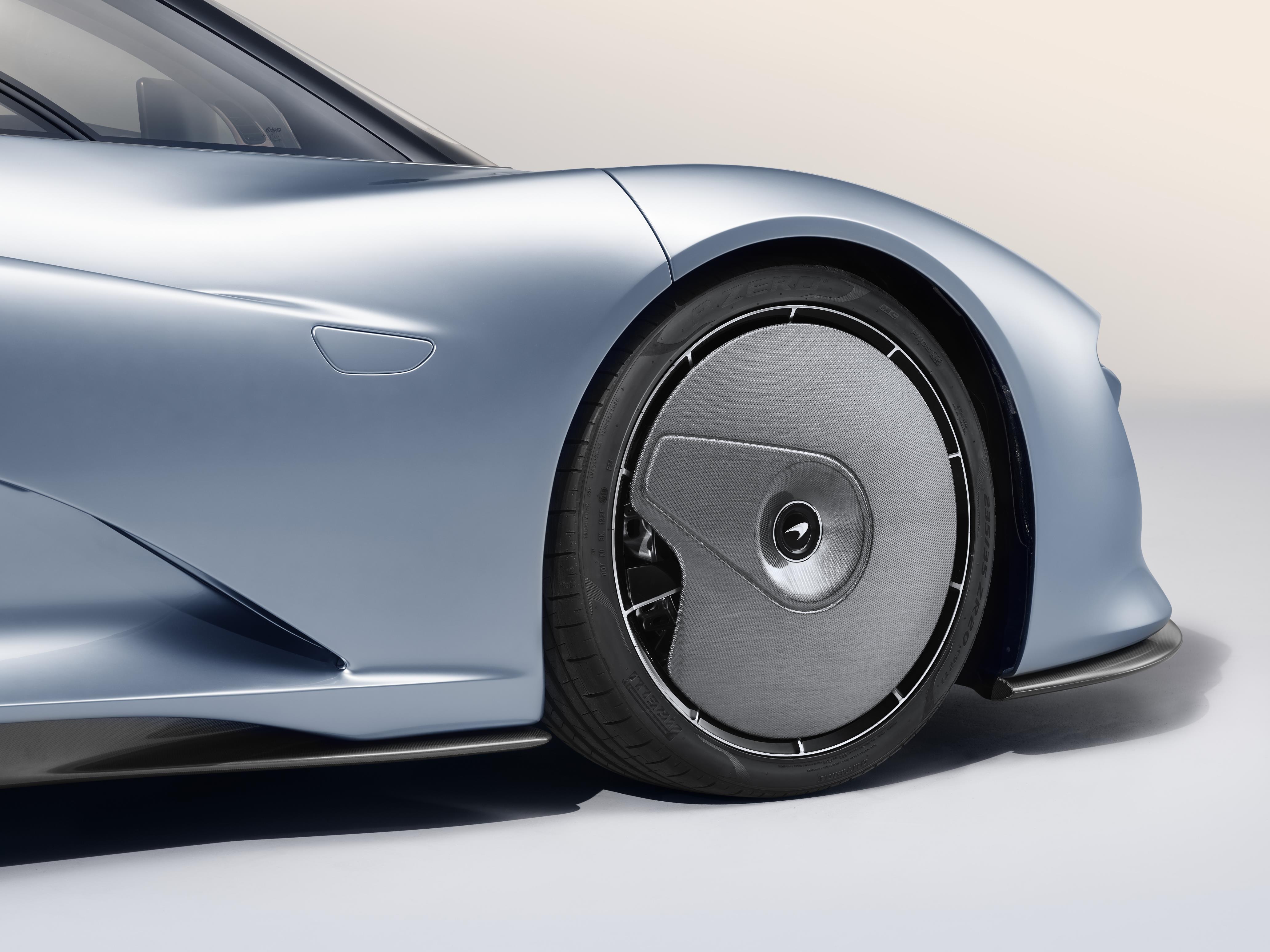

- Carbon fiber, front-wheel static aero-covers; retractable digital rear-view cameras in lieu of mirrors; and patented active rear ailerons all contribute to aerodynamic excellence

- Double-skinned, power-operated dihedral doors with single-piece ‘wrapover’ lightweight glazing

- Interior design and specification realize a new level of technical luxury

- Advanced electrochromic glass darkens top of the windscreen at the touch of a button, removing the need for sunvisors

- Introduces a new standard of bespoke customization, including interwoven carbon titanium deposition materials and digitally embossed, full-aniline and lightweight leathers

- First of 18 new cars or derivatives to be announced under the Track25 business plan

- McLaren Speedtail recently revealed to future owners and McLaren customers at a private event in London

McLaren Automotive today reveals the stunning, streamlined form and sensational specification of the McLaren Speedtail. The next chapter in McLaren’s Ultimate Series, the Speedtail is the first Hyper-GT from the pioneering British company recognized for producing luxury sportscars and supercars that deliver extraordinary driving experiences. The Speedtail can achieve the highest maximum speed of any McLaren to date, reaching 250mph, yet will also deliver an unprecedented blend of contemporary craftsmanship, materials innovation and bespoke personalization. Just 106* will be created and all are already reserved, at a price of £1.75 million plus taxes.

As the most powerful and most aerodynamically drag efficient McLaren, the Speedtail can exceed the 243mph record peak speed of the legendary McLaren F1, a feat made possible by intense collaboration between McLaren’s design and engineering teams to deliver a peerless blend of aerodynamic, powertrain and dynamic excellence. It is also significant that this is the first of 18 new cars or derivatives that McLaren will introduce as part of its Track25 business plan.

The teardrop-shaped cockpit and aerodynamically optimized body are the foundation for the exceptional aerodynamic drag efficiency, with innovative features such as carbon fibre front-wheel static aero covers, retractable digital rear-view cameras (in lieu of mirrors) and patented active rear ailerons furthering contributing to the ultra-low drag achieved.

The Speedtail model is built around a bespoke McLaren Monocage carbon fibre structure and benefits from lightweight engineering throughout, including an all-carbon fibre body, aluminum active suspension and carbon ceramic brakes. The powertrain is a pioneering petrol-electric hybrid developing a combined 1,035bhp to support the extraordinary performance.

A speed of 250mph is achieved in a unique Velocity mode, which has been developed specifically for the Speedtail. Velocity mode optimizes the hybrid powertrain for high-speed running while also tailoring the angle of the active rear ailerons. Additionally, the digital rear-view cameras can be retracted to further improve drag. Furthermore, the Velocity Active Chassis Control can lower the Speedtail by 1.4in, leaving the highest point of the vehicle just 3.7ft (1,120mm) from the road surface.

The hybrid powertrain enables a relentless increase in vehicle speed regardless of engine rpm and the low weight of the Speedtail – only 3,153lbs (1,430kg) dry – hastens this ability. The straight-line acceleration of the Speedtail sets a new benchmark for a McLaren, with 0-186mph achieved in just 12.8 seconds; McLaren Automotive’s previous Ultimate Series hybrid, the McLaren P1™, could reach this speed in 16.5 seconds. A bespoke P-ZERO™ tire designed for the Speedtail’s extreme speed has been developed with McLaren technology partner, Pirelli.

Being at the wheel of a Speedtail promises to be a truly sensational experience and unlike that enjoyed in any other car. The driver is positioned centrally in the luxurious cockpit, with seating for two additional passengers set slightly rearwards. There is luggage space within both the nose and tail of the vehicle and a bespoke luggage set is available to every owner, the carbon fiber, leather and metalwork on the cases being matched to the interior specification of their Speedtail.

Speedtail depositors were invited to view a design model of the car at a recent private preview event held in London. Resplendent in Speedtail Silver, a Nano-metallic, ‘molten-effect’ paint developed by McLaren specifically for this car, the model displays both aniline leather – a leather dyed with soluble dyes to retain the hide’s natural surface – and a new lightweight leather. The cockpit provides enticing glimpses of the astonishing level of personalization opportunities available; with each Speedtail being tailored to the owner’s individual tastes by McLaren Special Operations (MSO), the division of McLaren Automotive responsible for bespoke customer commissions, it is virtually certain that no two examples will be identical.

Streamlined simplicity is the key to true elegance

The essence of the McLaren Speedtail is modern design and craftsmanship in the truest sense, the breathtakingly sophisticated shape having been brought to life using the very latest digital development technologies. By radically rethinking every aspect of the exterior design and drastically reducing weight, aerodynamic drag efficiency was maximized, acceleration improved and top speed increased.

Elegance has been created through reduction: every body panel is carbon fiber and has been sculpted to reduce drag; retractable digital rear-view cameras replace traditional door mirrors to further aid aerodynamic performance; carbon fiber front-wheel static aero covers reduce air turbulence around the wheelarches; and the seamless silhouette is enhanced by a reduction in the number of shutlines – including a one-piece rear clamshell – which disrupt neither the visual continuity of the body or the flow of air over it. The patented active rear ailerons ensure the continuity of the design remains uncompromised, with drag kept to a minimum.

Every element and every aspect of the McLaren Speedtail has been considered in the mission to reduce drag and maximize top speed. The McLaren Speedtail is narrower than a McLaren P1™, but more than half a meter (more than 1.6ft) longer, measuring nearly 17 feet (5,137mm) from nose to tail. The purity of form is remarkable: viewed from above, the McLaren Speedtail is essentially a teardrop – the fastest shape in nature – and this sculpted form creates the smoothest initial contact with the air at the front splitter, while the dramatically elongated tail bleeds off the flow to reduce turbulence. And not only is the overall shape a teardrop, but so too is the cockpit glasshouse set within the body, once again benefitting aerodynamic drag efficiency.

The vertical ducts beneath the full LED headlights, for instance, are particularly slender, their form meticulously tapered to minimize drag while still feeding sufficient cooling air into the LTRs (Low-Temperature Radiators). Airflow that doesn’t enter the LTR ducts is directed over the bonnet of the Speedtail and enters two discreet upper front clam intakes. From here, it is ducted through the body and around the wheelarch before exiting out of the lower door vents. This engineering detail reduces the volume of air traveling around the side of the vehicle, which is prone to separation from the body and resulting turbulence.

The residual airflow over the nose of the car is directed onto and over the windscreen by a cowling at the trailing edge of the bonnet. Engineered to completely encompass both the single-arm wiper and its operating mechanism, the cowling maintains a smooth flow transition across the front of the Speedtail and then over the roof towards the powertrain’s ‘snorkel’ intake. This inlet, which provides the air intake for the internal combustion engine element of the petrol-electric powertrain, is set flush within the roof to reduce drag and cannot be seen when the McLaren Speedtail is viewed in profile.

The required flow of air to the powertrain is maintained with two intakes that slope downwards, starting just behind the glass canopy. The intakes – which are split by the central high-mounted stop light – curve down into the engine cover before disappearing from view; a shorter, more aggressive intake would cause the air to separate from the surface and pass over the intake.

One of the innovations immediately obvious on the McLaren Speedtail is the introduction of lightweight, carbon fibre front-wheel static aero covers. Incorporated into the 20-inch, 10-spoke forged alloy front wheel design to minimize aerodynamic drag, they remain fixed in position as the wheels rotate, the flat surface smoothing airflow around what would otherwise be a turbulent aerodynamic area. Typically, the revolution of a wheel drives air away from the vehicle, but the carbon fiber front-wheel static aero covers keep the air ‘attached’ to the car and guide it onwards to the door blades on the leading edge of the dihedral doors.

The static wheel covers work in conjunction with multiple ducts and air paths to reduce turbulent air within the wheelarches. As air passes out of the LTRs, for instance, it is vented into the front wheelarches. From there – together with heat energy generated by the lightweight, carbon ceramic braking system – the air is channeled through the ducts in the fixed front wheel aero cover in a consistent flow pattern. Pressure within the wheelarches is also reduced via the lower door vents, which draw the turbulent air created by the rotating front wheels out of the arches and drive it smoothly along the sides of the McLaren Speedtail. The wheels themselves are finished in an elegant gloss black, with diamond-cut finishing. Brake calipers in Speedtail Silver complement the lustrous body color.

Door mirrors are notably absent, the McLaren Speedtail instead featuring two discreet, high-definition digital cameras that glide out of the doors when the vehicle ignition is activated. Traditional fixed door mirrors create a surprising amount of air turbulence, but with a significantly smaller profile, the cameras on the Speedtail have only a minimal effect on airflow; furthermore, they provide a much wider field of view of the road behind. The camera feed is displayed on two screens, positioned at either side of the instrument panel in front of the driver. When Velocity mode is selected, the cameras retract into the doors, reducing drag further still.

Utilizing the same aerodynamic principles proven on the McLaren P1™, second-generation McLaren Super Series and McLaren Senna, intakes for the HTRs (High-Temperature Radiators) are mounted on the shoulders of the Speedtail, within the double-skinned dihedral doors. The raised front wings, compact cockpit glasshouse and flush glazing serves to keep the airflow attached to the vehicle, and drive it over the front fenders and into the deep channels within the doors to provide cooling for the 1,035bhp hybrid powertrain. Such is the efficiency of this solution that the HTR intakes of the McLaren Speedtail are particularly compact, further minimizing drag.

The trailing edge of the Speedtail showcases a particular highlight, namely a pair of active rear ailerons. These dynamic elements are hydraulically actuated and an integral part of the rear clamshell, formed in flexible carbon fibre; the body of the Speedtail can quite literally bend. With a tolerance of only 1mm between the surfaces, this dramatic new technology all but removes any gaps or shutlines between the vehicle and the leading edge of the spoilers, meaning there is no turbulent air, no drag and no loss of speed.

Positioned outboard from the center of the Speedtail for optimal aerodynamic performance, the twin active ailerons adjust to move the center of pressure and provide the required level of downforce precisely when it is needed most, for instance under deceleration to provide an airbrake function, while at high speed to increase vehicle stability.

Performing a similar function to that of the lower door vents, the vertical rear blades that are located beyond the trailing edge of the rear fenders draw turbulent air out of the rear wheelarches, away from the 21-inch forged alloy, rear wheels. By reintroducing this ‘dirty’ air into the external environment as smoothly as possible, the base pressure behind the Speedtail is reduced – and so therefore is drag.

The rear diffuser of the McLaren Speedtail works in conjunction with the rear blades to reduce base pressure and drag, achieving this through the fluent merger of the airflow from the top and the underside of the vehicle. The extended length of the diffuser and flat underfloor combine to diffuse the airflow before – in conjunction with the extended rear bodywork of the Speedtail – introducing it gradually back into the freestream rather than separating it from the rear of the vehicle with a hard, abrupt edge. The result is a further improvement to aerodynamic drag efficiency.

On the design model produced to herald the next Ultimate Series, the McLaren badge and Speedtail name are formed in 18-carat white gold, with the letters individually pressed, clipped and polished.

Beautifully tailored luxury, of your own creation

A Speedtail driver’s seat is positioned – literally – at the center of the cockpit. This creates an unparalleled sense of space and a perfectly balanced view out of the windscreen. The custom-made carbon fiber seat, inspired by the seat of the iconic McLaren F1, offers the support and comfort appropriate for a ‘Hyper-GT’ car. Entry into this very special driving position is aided by a newly created directional leather finish that makes it easy to slide into the seat but then subtly holds the occupant in place while they drive. The central seat is flanked by two passenger seats that are integral to the carbon fiber monocoque.

The windscreen curves upwards to become part of the roof, meeting a glazed porthole above the driver’s head and the glazed upper section of the dramatic dihedral doors. The incredible sense of space continues rearwards with glass rear-quarterlights that stretch back behind the seats to almost level with the rear axle. An extraordinary amount of light streams into the cockpit – unless the occupants choose otherwise, in which case the porthole, glazed upper section of the doors and rear-quarterlights feature electrochromic technology that allows them to independently turn opaque in an instant. Separately, the top of the windscreen is also electrochromic glass, forgoing the need for sun visors.

Ahead of the driver is a state-of-the-art control system, with high-definition displays and touchscreens that sweep across the dashboard and remove almost every button and switch traditionally found in a car. The controls to start the engine, turn on the Active Dynamics Panel and engage Velocity mode – as well as those to open the windows and doors – are in panels above the driver’s head. These controls and the other switches and dials are milled from aluminum, and then hand-brushed and polished.

The beautifully crafted interior fuses contemporary craftsmanship and cutting-edge innovations to push the boundaries of design into a new era. The elegance and material excellence is more akin to high fashion, luxury yachts and bespoke furniture than is normally seen within an automotive environment. The scope for personalization is extraordinary and every Speedtail will be unique to its owner.

McLaren’s vision for the Speedtail – to create the ultimate in bespoke vehicle design – begins with carbon fibre, a material that McLaren has pioneered for nearly four decades, with every road or race car it has built since 1981 having a strong, stiff and light composite structure at its core. The Speedtail marks a revolutionary advance in the creation and usage of carbon by McLaren, with state-of-the-art technologies combining with traditional Italian textile knowledge to conceive a ‘digital loom’ process that delivers an even lighter composite material formed from an intricate carbon fibre weave.

Pursuing further innovation, McLaren utilized this digital loom technique to develop a unique carbon fibre and titanium weave, christened Titanium Deposition Carbon Fibre. Traditional methods to change the color of carbon fibre can compromise the material’s structural integrity and visual clarity; for the Speedtail, a micron-thin layer of titanium is fused directly onto the weave and becomes an integral part of the carbon fiber’s construction. The titanium deposition process maintains immense strength and low weight and creates a truly remarkable finish of visual carbon fiber with a chrome-effect shimmer.

The front splitter, diffuser and side skirts are all finished in 1K Titanium Deposition Carbon Fibre. This material has just 1000 fibers per thread, making it lighter than the 3K alternative and allowing the adoption of a Jacquard weaving process to create an intricate, bespoke pattern in the Visual Carbon Fibre elements. The titanium can additionally be anodized in any bespoke color or used to create interwoven images, symbols or even words within the carbon – for example, the rear of the driver’s seat features the McLaren logo.

Working in collaboration with expert Swiss watchmaker, Richard Mille, McLaren used pioneering horology techniques to develop a world-first in the automotive sector: Thin-Ply Technology Carbon Fibre (TPT). The material is comprised of countless ultra-thin carbon layers just 30 microns in depth, each positioned at a 45° angle. The surface is then delicately milled to expose a stratified, shimmering construction that resembles flowing water. This fusion of cutting-edge technology and design with precision engineering is truly unique, and can be integrated into areas of the Speedtail such as the overhead control panel, gearshift paddles and steering wheel clasp. TPT is also used in combination with 18-carat white gold to create the McLaren badge on the front of the first Speedtail design model.

The entire interior of the Speedtail has been designed to cosset and embrace the driver and their passengers, with the finest hides enveloping almost every surface. The driver’s seat on the Speedtail design model is trimmed in Dark Glacier and Cool White leathers, the former a full aniline material and the latter a new, semi-aniline lightweight leather, developed by the Bridge of Weir Leather Company. The luxurious thickness and supple finish of the leather – the result of using only the finest hides sourced from the best heritage breeds, combined with generations of hand-finished craftsmanship – is unaffected, but by infusing air beneath the surface during the manufacturing process, material density is reduced and the weight cut by 30 percent. The result is proof that luxury can go hand-in-hand with lightweighting.

The lightweight leather can be treated to render it resilient enough to line the floor of the Speedtail and finished in the color or colors of the owner’s choice; in the design model, Dark Glacier and Black have been selected. The leather then extends in a continuous piece to provide covers for the storage compartments beneath the seats, McLaren’s designers drawing on the natural traits of the leather and its inherent rigidity to allow the compartments to open like a piece of luxury luggage.

Specially selected Scandinavian hides are used for the full-aniline leather that trims the dashboard and passenger seats. Unblemished and virtually unchanged from its natural state, this leather is the result of a five-week tanning process using vegetable oils the only addition is the chosen color – in the case of the passenger seats, Dark Glacier – producing a rare automotive material of truly exceptional quality. The finish of the rich leather is almost impossibly soft to the touch and like the grain of a tree or a human fingerprint, the individual patina of the hide is preserved so that every surface is utterly unique in character.

Speedtail owners can additionally select unique stitch patterns in whichever color they wish and bespoke decorative forms can be created within the leather through digital quilting or unique debossed or embossed patterns. Inspired by the finest of furniture and fashion design, the trimmed edges of the leather can even be painted, the color being hand-mixed, hand-painted and then hand-polished to elevate the leather craftsmanship to the highest possible level and deliver an uncompromised aesthetic.

The limited production of the Speedtail has given McLaren the opportunity to push color and materials design into unchartered territory and owners will experience an unprecedented journey of vehicle personalization, leading up to the beginning of 2020 when the first deliveries of this rarest of Ultimate Series McLaren will take place.

* 106 examples of the McLaren F1 were sold

| PERFORMANCE | |

|---|---|

| Maximum Speed | 403kph (250mph) |

| 0-100kph (62mph) | 3.0 seconds |

| 0-200kph (124mph) | 6.6 seconds |

| Maximum Power | 1070PS (1036bhp) |

| Maximum Torque (Nm (lb-ft)) | 1150 (848) @ 5,500-6,500 rpm |

| ENGINE | |

| Engine Capacity | TBA |

| Type | V8, 4.0L with eMotor |

| Technology | Twin-Turbocharged V8 Engine with parallel hybrid system |

| BRAKING | |

| 100-0kph (62-0mph) | 32 metres (105 feet) |

| 200-0kph (124-0mph) | 132 metres (433 feet) |

| EFFICIENCY* | |

| CO2 Emissions: Weighted Combined (WLTP) | 357 g/km |

| Fuel Efficiency: Weighted Combined (WLTP) | 15.6 litres/100kms (18.1 mpg) |

| WEIGHT | |

| Dry Weight (Lightest) | 1,430kg (3,153lbs) |

| DIN Kerb Weight | 1,597 kg (3521 lbs) |

FIRST McLAREN SPEEDTAIL ATTRIBUTE PROTOTYPE, ‘ALBERT’ SQUARES UP TO RIGOROUS REAL-WORLD TESTING

- McLaren’s new ‘Hyper GT’ embarks on year-long test regime underpinning development of new center-seat, 250mph hybrid

- Closed-facility testing of the fastest McLaren ever now underway; public road trials due to commence in December 2018

- Attribute prototypes join Speedtail ‘mules’ in ongoing durability testing

- First attribute prototype affectionately christened ‘Albert’, in tribute to its famous McLaren F1 forebear that was designed in Albert Drive, Woking, Surrey UK

- First customer deliveries of McLaren Speedtail due early 2020

The first hybrid powertrain prototype of McLaren Automotive’s breathtaking new Ultimate Series flagship, the McLaren Speedtail, officially embarks this week on a year-long test regime that will underpin the development of the first McLaren Hyper-GT. The punishing test program in the run-up to production commencing at the end of 2019 will see Speedtail prototypes running in Europe, North America and Africa, initially at bespoke automotive test facilities but later amongst traffic on ‘normal’ roads.

Deployment of the first Speedtail attribute prototype marks an exciting new stage in the development of the fastest, most aerodynamic and most luxurious McLaren ever made. The prototype is officially designated MVY02* but echoing the naming of development test mules of its legendary forebear, the 1992 McLaren F1, has been christened, ‘Albert’. This is a respectful reflection not only on the name of the McLaren F1 mule ‘Albert’ but also the Albert Drive premises in which the F1 was designed.

Distinguished by a unique testing livery, ‘Albert’ has a production-specification chassis and petrol-electric hybrid drivetrain, as well as the unique three-seat cockpit with central driving position. As the development and validation program progresses every aspect of the Speedtail’s performance will be honed as the full 1,035bhp available to Speedtail drivers to propel the prototype to 250mph is used – including in high-speed trials with McLaren Automotive Chief Test Driver and former IndyCar champion Kenny Bräck at the wheel.

“The start of real-world testing represents a major step in the development of the McLaren Speedtail. As the first fully representative prototype, ‘Albert’ will build on the invaluable work still being put in by earlier development cars, allowing us to sign-off vehicle attributes including chassis dynamics; brake performance; damper tuning; tires; NVH and aspects of ergonomics and comfort. With a huge amount achieved already, the McLaren Speedtail is well on the way to fulfilling its destiny as the greatest McLaren road car ever.”

Ben Gulliver, Head of Vehicle Development, McLaren Automotive

The central driving position and three-seat layout of the Speedtail was pioneered by the iconic McLaren F1 in 1992. This configuration is uniquely McLaren, remaining exclusive among production cars until McLaren Automotive confirmed in November 2016 that it would be reprised for the next Ultimate Series model, then codenamed BP23.

The center-seat layout of the Speedtail was first publicly demonstrated in a ‘proof of concept’ model that was simply a McLaren 720S reconfigured with a single, centrally-mounted driving seat. Four further mules followed and these will continue to be used around the world for performance and durability testing, alongside the prototype vehicles.

Despite its test livery and the bodywork from the A-pillars forward, ‘Albert’ is fundamentally a Speedtail, with shape-representative body panels and dihedral doors around the unique carbon fibre McLaren Monocage core structure. The production-level specification allows Speedtail attributes to be proven in real-world conditions early in the development process, including for example ingress and egress to the three-seat cockpit.

Production of the £1.75 million (plus local taxes) McLaren Speedtail is due to commence at the end of 2019, with first deliveries in early 2020. As with the McLaren F1, 106 cars will be available and all have already now been allocated to owners.

*The Speedtail project name MVY0 combines McLaren’s usual MV project initials with the letters Y0, which signify the lateral central point in the XYZ axis in CAD (computer aided design).