Innovation, more than ever, lies at the heart of Renault’s brand identity. The latest vehicles to have been unveiled, as well as those due to be revealed in the coming months, all carry the genes of this quest for innovation through the new techniques and technologies they pack, all of which are focused on the needs and expectations of motorists. All these innovations contribute directly to the affordable mobility that Renault is striving to deliver to its customers day after day.

Innovations@Renault offers a chance to discover Renault’s latest technological breakthroughs and this year’s edition shines the spotlight on two areas: innovations which help to enhance travelling comfort, driving pleasure and occupant wellbeing, plus those which endeavour to minimise CO2 emissions and the impact of motoring on the environment thanks to ongoing improvements to the energy efficiency of the brand’s engines, electric motors and vehicles.

At the same time, Innovations@Renault provides an opportunity to view certain research projects and demonstration vehicles that are currently being developed in association with private and public partners and which explore some of the technologies that are in the pipeline for the future.

Innovations@Renault showcases the guidelines and priorities that are in place for research and advanced projects, the results of which will be visible on the brand’s vehicles and powertrains in the years ahead.

“Renault’s determined and proactive approach to innovation is a major driving force of the Renault 2016 Drive The Change plan,” says Rémi Bastien, Engineering Innovation Director, Renault. “The Innovations@Renault programme offers a rare chance to dialogue with our experts. It also serves as a valuable opportunity for the men and women behind these innovations at Renault to express their vision and passion for the technologies that are key to the company’s future.”

CONTENTS

01

WELL-BEING ON BOARD

Innovations in favour of occupant wellbeing and driving enjoyment

Cockpit display technologies : Intuitive and easy to use displays

Smart chassis : Technology-enhanced driving pleasure

ADAS* : Advanced Driving Assistance Systems

02

MINIMISING CO2 EMISSIONS AND ENVIRONMENTAL IMPACT

Downsizing and reducing weight to maintain the Renault Group’s lead

New engine integration architecture : Downsizing opens up the way for new vehicle architectures

Twin-turbocharging : Optimised torque management at all engine loads

Steel pistons inspired by F1 Design : reduced friction

Weight savings: large glass tailgate bonded to lightweight a frame

03

RESEARCH PROTOTYPES

Cars connecting to environment

PAMU**: the autonomous ‘valet’ service

SCORE@F***: Intelligent co-operative transport system

* Advanced Driving Assistance Systems

** Advanced urban mobility platform

*** Intelligent co-operative transport system

01

WELL-BEING ON BOARD

Innovations in favour of occupant wellbeing and driving enjoyment

Innovation is a longstanding tradition at Renault and has always sought to make motoring easier and more enjoyable. The objective is to make time spent on the road a pleasurable experience for all occupants. To achieve this, Renault’s holistic approach puts people at its centre in order to determine the most effective ways of enhancing travelling comfort (cabin space, comfort, wellbeing, etc.), performance (road holding, ride comfort, etc.) and safety.

The biggest challenge is to develop user-friendly solutions that not only stand out among the very best but which are also an affordable reality for all motorists! To meet this objective, we are actively pursuing our research efforts to enhance travelling comfort and facilitate driving through work in areas such as vehicle modularity, multimedia systems, driver aids, cabin space, vehicle manoeuvrability, acoustic comfort, usability, health, wellness, etc.

The effervescence of today’s digital world provides the automobile industry with countless opportunities to bring motorists an increasingly broader spectrum of services and features. However, it also presents a number of risks inasmuch as this cascade of new functions and their associated displays, buttons and menus could quite easily become a distraction for occupants and even jeopardise safety.

Renault is perfectly aware of this risk and is doing its utmost to ensure that these technological advances serve exclusively to bring added value to the wellbeing of occupants by making their lives easier and keeping them in touch with their environment without compromising their safety. Striking the right balance between the benefits brought by these new functions, travelling comfort and safety depends to a large extent on the relevance of the human-machine interfaces developed for vehicles.

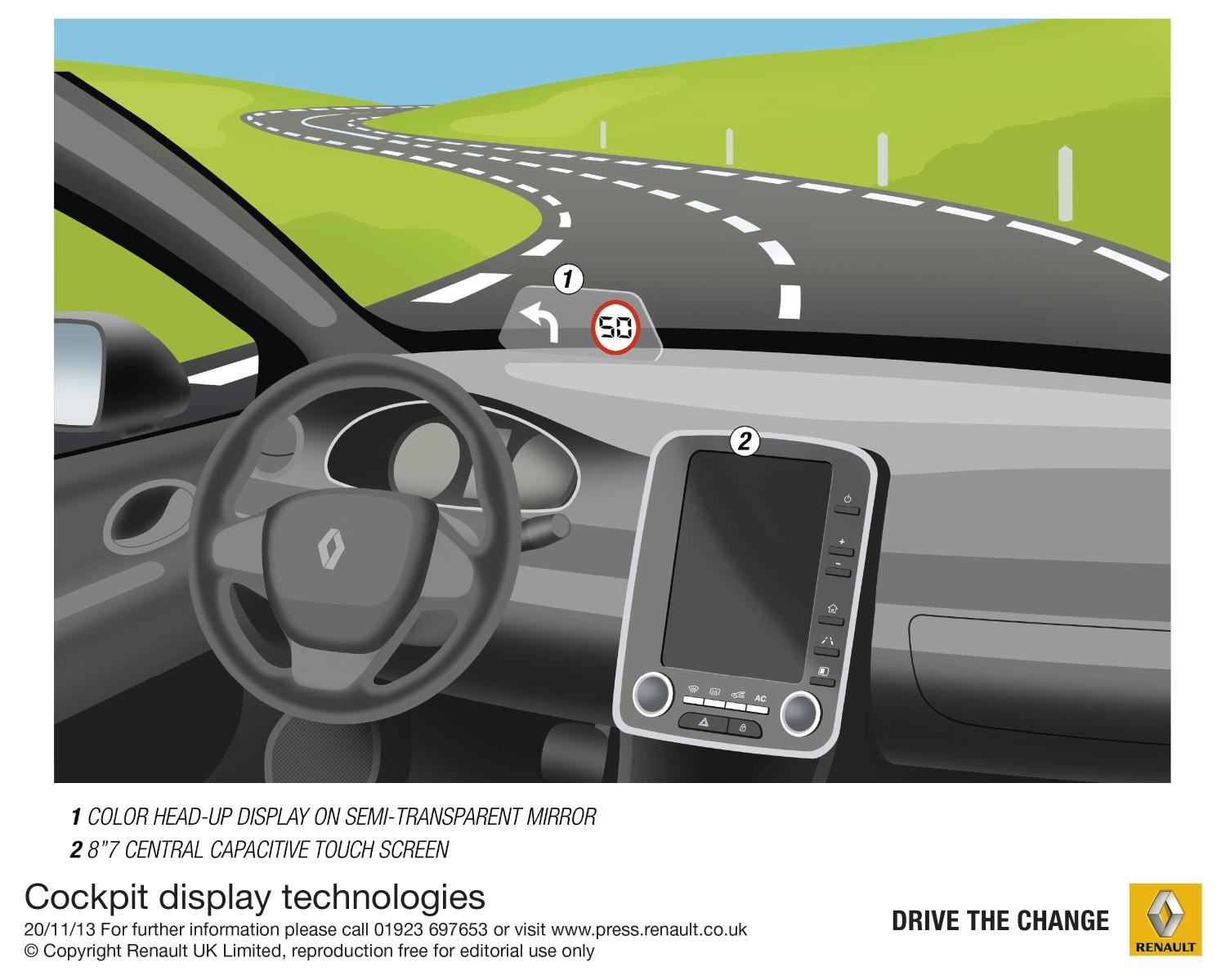

- COCKPIT DISPLAY TECHNOLOGIES:

Intuitive and easy to use displays

A golden rule for the specialists behind the latest automotive human-machine interfaces is to ensure that drivers do not need to take their eyes off the road for more than 1½ to two seconds. This consideration is a fundamental cornerstone of the legislation that applies in this field.

The positioning of the controls and displays located within the driver’s immediate environment is consequently calculated to comply with this imperative, while the technologies themselves must be both intuitive and simple to use. When developing HMIs, Renault is careful to reduce the cognitive workload associated with using the many sources of in-car information (live services, ADAS, communication, infotainment, etc.).

Thanks to the possibilities opened up by new technologies, the quality, usability and integration of the displays needed to deliver all this information is evolving quickly.

Two of the technologies that Renault has developed in this field are :

- A head-up HD colour display system

- A big capacitive 8.7-inch central display

HOW DOES IT WORK?

The head-up displaysuperimposes driving-related information in the driver’s field of vision to minimise the need for head movement. The enlarged image from a small high-resolution (298ppi) colour screen is projected by reflection onto a transparent, aspheric strip situated on top of the dashboard.

The capacitive 8.7-inch central touchscreen display is of the same type as the screens employed for smartphones and tablets, but developed specifically for automotive use. These intuitive displays are ideal for automotive applications since they are user-friendly and reduce the cognitive workload by providing the same touch quality and functions that drivers have become accustomed to with their cell-phones and tablets.

The capacitive technology has been adapted in terms of both its usability and strength for use in an automotive environment. The screen is capable of withstanding extreme low and high temperatures ranging from -35°C to +85°C (-40°C to +95°C when the vehicle is stationary), while at the same time ensuring optimal readability in all conditions of brightness and contrast. The display’s size permits the incorporation of numerous functions and controls instead of the more traditional buttons and switches.

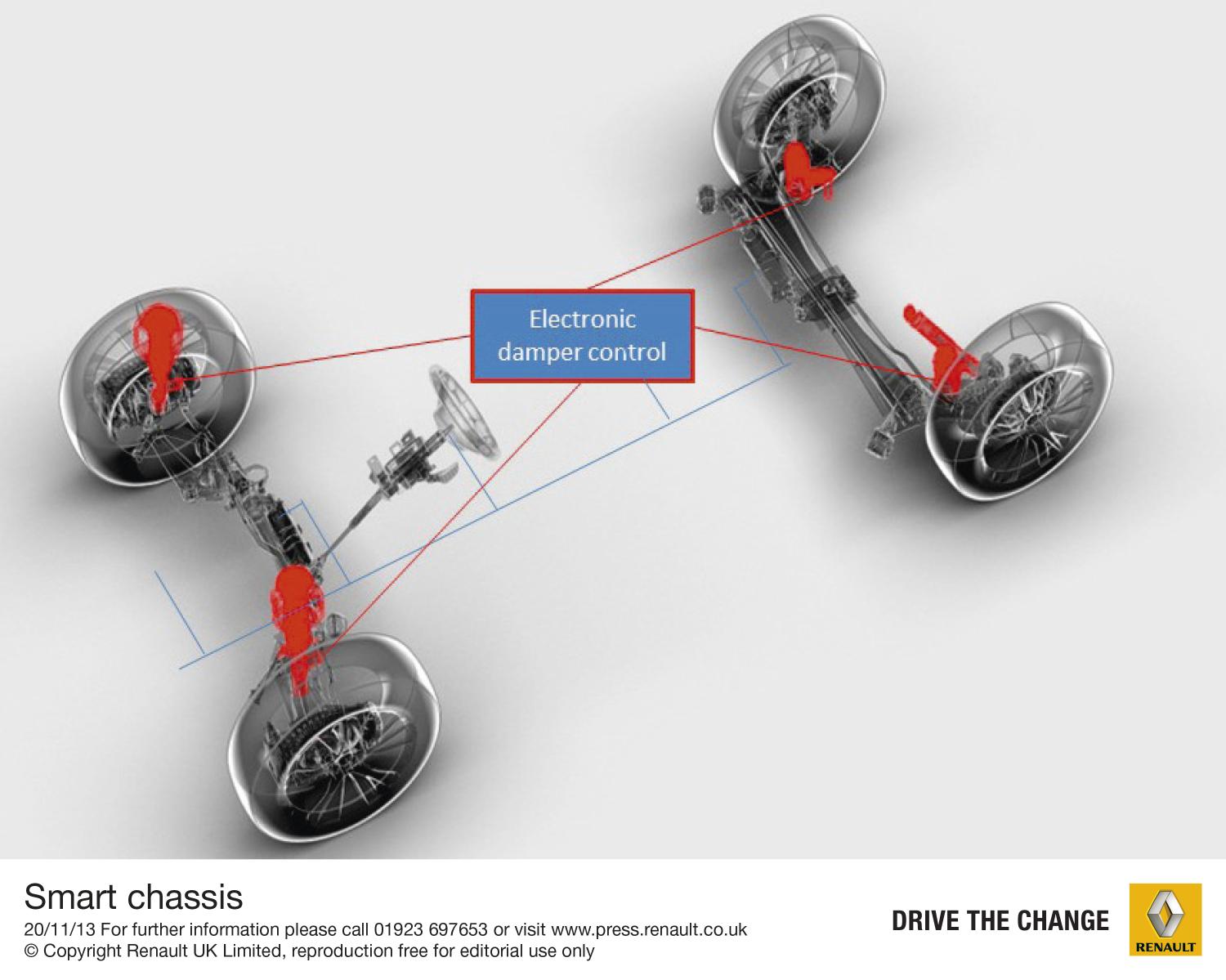

SMART CHASSIS:

Technology-enhanced driving pleasure

HOW DOES IT WORK?

The system comprises two elements:

- An electronic damper control system which delivers optimum comfort by softening the effects of uneven road surfaces thanks to a choice of settings (‘comfort’ or ‘sport’) which either place the emphasis on passenger comfort or favour road holding should the driver prefer a sportier, more abrupt driving style, while still optimising ride comfort, of course.

- The new-generation 4Control chassis adjusts the performance of the four-wheel steering system as a function of the selected mode to provide a level of manoeuvrability more readily associated with small city cars.

Thanks to these two systems, drivers are able to adjust parameters such as pedal mapping and steering wheel effort to match the way they wish to drive without detracting from either handling performance or safety.

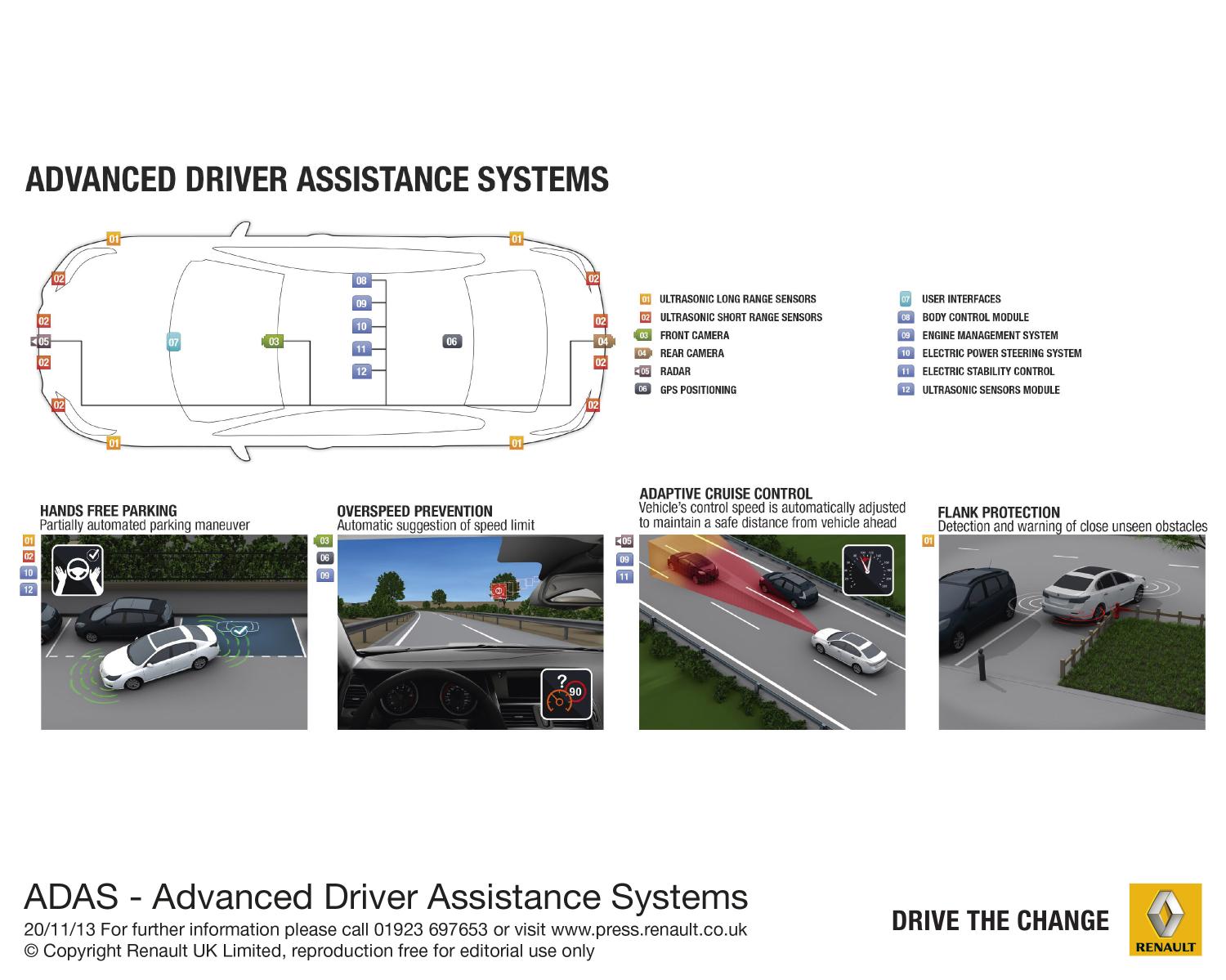

2. ADVANCED DRIVER ASSISTANCE SYSTEMS (ADAS):

Monitoring the vehicle’s immediate environment to assist drivers

HOW DOES IT WORK?

As their name implies, ADAS (Advanced Driver Assistance Systems) assist drivers by providing them with real-time information about their vehicle’s immediate environment.

The system’s two cameras, 12 ultrasonic sensors and radar collect data which is processed in real time by dedicated computers.

The resulting information is then communicated to the electric power steering, ESC and engine control units, etc., to assist the driver thanks to functions such as Easy Park Assist, ACC (Adaptive Cruise Control), distance warning and overspeed protection with traffic sign recognition.

02

MINIMISING CO2 EMISSIONS AND ENVIRONMENTAL IMPACT, Downsizing and reducing weight to maintain the Renault Group’s lead

The Renault Group is Europe’s number one car manufacturer for the low CO2 emissions performance of the passenger vehicles it sells (first half of 2013). This achievement was made possible thanks not only to the renewal of the group’s model range, but also to the success of its Energy engines and the sharp increase in sales of electric vehicles. This owes nothing to luck and fits perfectly with Renault’s powertrain strategy which seeks to position the Renault Group durably as a European leader in the realm of low CO2 emissions and fuel consumption.

The Renault Group’s strategy is founded on two axes:

- A commitment to electric vehicles, the only solution that permits zero emissions during road use. Renault is making ongoing improvements to this technology and is contributing actively to the expansion of the necessary infrastructure,

- Ongoing improvements to its range of internal combustion engines (downsizing, reduced friction, combustion efficiency, etc., and the increasing number of vehicles specified with Energy engines) and transmissions (gradual introduction of EDC/Efficient Dual Clutch transmission).

The pursuit of this goal to be the industry’s benchmark calls for widespread use of the technique of downsizing of internal combustion engines. Meanwhile, after standing out as a pioneer of the technology in the 1970s through motorsport, Renault is gradually extending turbocharging across its range.

Innovations@Renault sees Renault present three engine-related innovations which take this approach even further still:

– Twin-turbocharging to improve performance further while at the same time reducing fuel consumption and emissions.

– Tilted engines which take up less space.

– Steel pistons for reduced internal friction with F1-inspired geometry

Renault is also exploring ways to shave weight off its vehicles with a view to improving their energy efficiency. The use of lightweight components and functions means lower fuel consumption, and examples include the use of a glass tailgate bonded to a lightweight metal frame.

1. A TILT OF 49 DEGREES FOR THE THREE-CYLINDER ENGINE

Downsizing opens up the way for new vehicle architectures

The three-cylinder turbocharged 90hp petrol engine titled at an angle of 49°

HOW DOES IT WORK?

This innovation consists in modifying the Energy TCe 90 engine’s angle of tilt to permit its use when space is at a premium because of the vehicle’s architecture. The resulting angle led to the revision of approximately half its component parts.

The engine is equipped with an electric waste gate which is precision-controlled to minimise CO2 emissions and enhance driving enjoyment. It also comes with the recent innovations aimed at reducing friction (variable-displacement oil pump and special surface treatments, notably of the pistons and cam followers).

This innovation reduces the space taken up by the powertrain and opens up opportunities for new vehicle architectures.

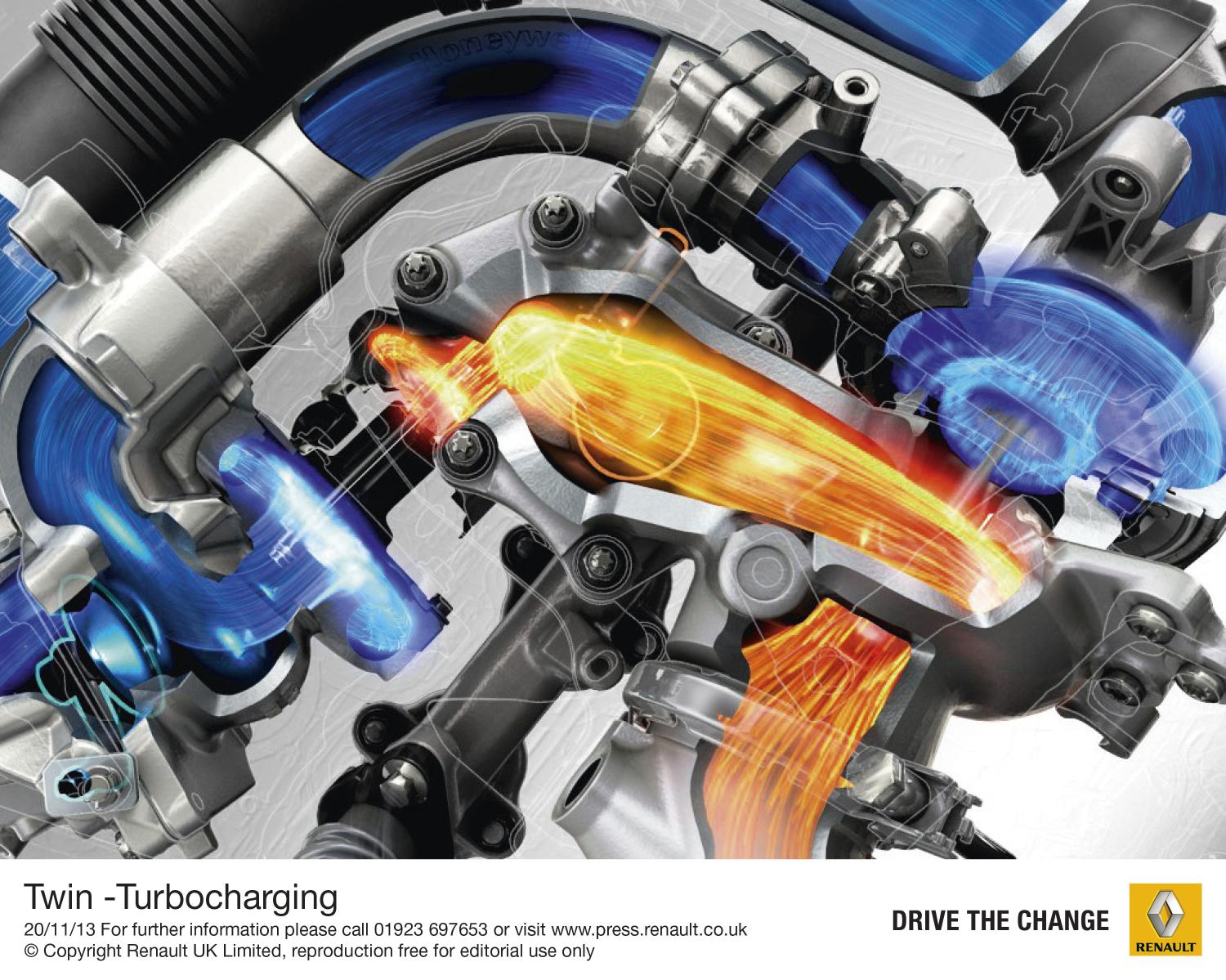

2. TWIN-TURBOCHARGING

Optimised torque management at all engine loads

HOW DOES IT WORK?

Twin-turbocharging opens up new opportunities for the downsizing of internal combustion engines in order to enhance driving enjoyment while at the same time optimising fuel consumption and CO2 emissions.

Used by high-performance diesel engines, this technology features two turbochargers in-line which enable acceleration response to be optimised at all engine speeds:

– The first turbo is of the very low inertia type and permits the delivery of high levels of torque (upwards of 220Nm/litre) at low engine speeds. The benefit is more responsive pull-away and mid-range acceleration performance.

– The second, bigger turbo functions in association with the first to provide high power (100hp/litre) at high engine loads, from mid-range revs.

The use of twin-turbocharging for diesel engines reconciles the quest for torque at low revs and high-end power. The engine functions at a speed that ensures optimal efficiency to provide low fuel consumption and CO2 emissions in line with the pleasure derived by the driver.

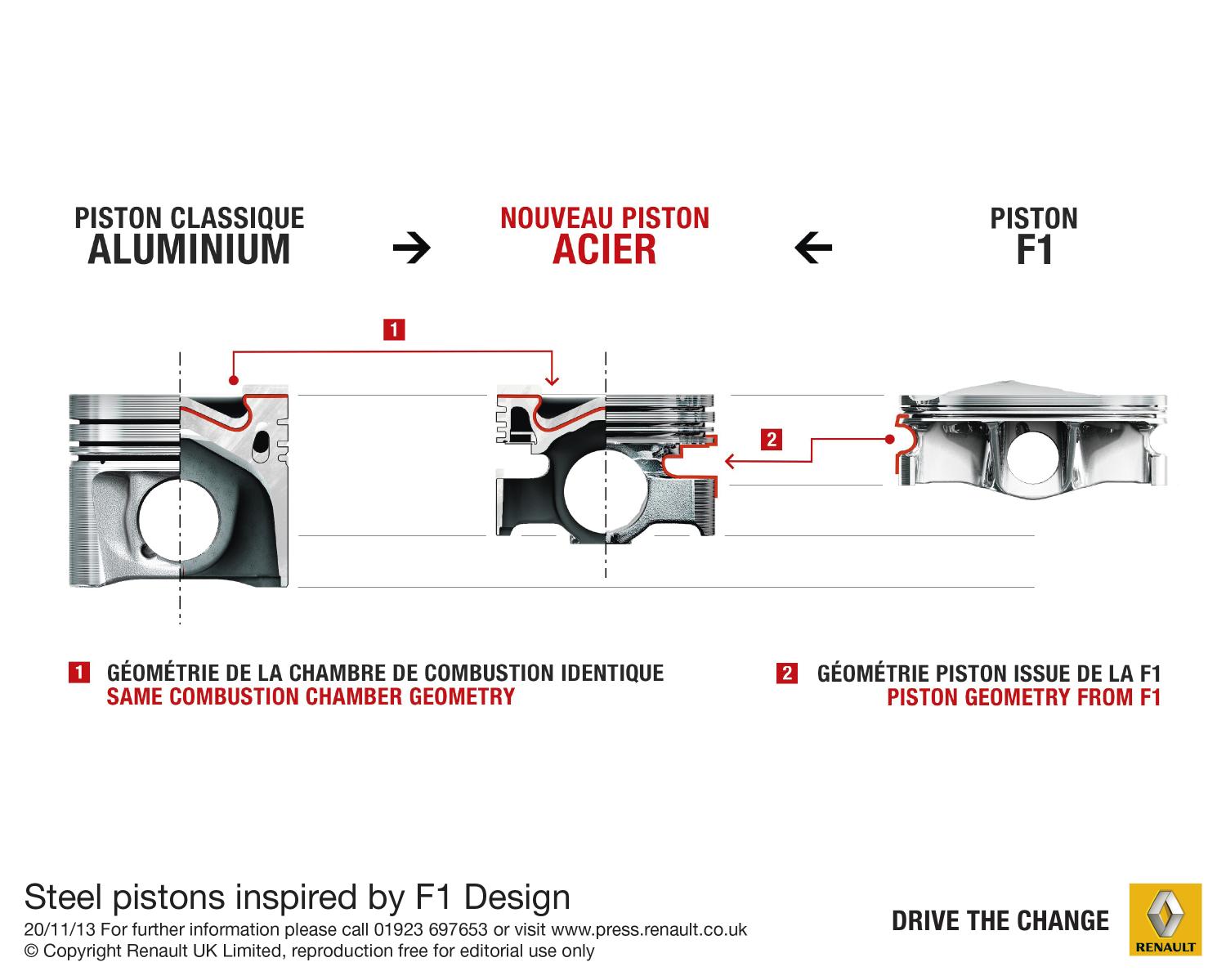

3. STEEL PISTONS INSPIRED BY F1 DESIGN

Reduced friction

HOW DOES IT WORK?

Given that steel dilates less than aluminium when hot, steel pistons dilate less than their aluminium counterparts, resulting in smaller clearances between the pistons and cylinder walls at high temperatures. There is consequently less friction which in turn enhances combustion efficiency for estimated CO2emissions savings of around three percent (NEDC cycle).

Although heavier, steel is also more rigid, which means that pistons can be machined along their length, allowing the skirts to be shortened to maintain the same overall mass as an aluminium assembly. This principle is similar to that seen in Formula 1. Indeed, Renault’s research and development work to improve its production engines capitalises on the brand’s expertise as an F1 engine maker which has seen it claim 12 Constructors’ world titles,.

4. WEIGHT SAVINGS

Large glass tailgate bonded to a lightweight metal frame

Eliminating excess kilograms makes a significant contribute to a vehicle’s energy efficiency. Vehicle weight has the biggest influence on CO2, and the ratio between a vehicle’s CO2 emissions and its mass can be described as 1-to-10,000. In other words, a weight-saving of 10kg results in a 1g/km saving in CO2emissions during road use.

Renault is consequently working on new designs and manufacturing processes which seek to achieve valuable vehicle weight reductions.

HOW DOES IT WORK?

The glass of a conventional tailgate is bonded to a metal hatch (frame + skin). In this case, however, and for the first time, a large glass panel is bonded directly to a lightweight frame. The challenge consisted in incorporating the different ancillaries (wiring, stops, logo, lip spoiler mounting). The weight saving compared with a conventional tailgate is 2.5kg.

03

RESEARCH PROTOTYPES

Cars connecting to environment

Thanks to progress made in the fields of digital technology and interconnectivity, vehicles will eventually be capable of exchanging information between themselves (vehicle to vehicle) and with road network infrastructure (vehicle to infrastructure). The additional assistance this will bring motorists will gradually free them from certain tasks with a view to reducing their cognitive workload and permitting them to do other things. Delegating driving in certain conditions in this way is a reassuring means to provide drivers with extra time. At the same time, cars are more connected to their immediate environment, allowing them to gradually become part of a global mobility system.

The ‘voitures à vivre’ of tomorrow

Renault’s R&D experts are stepping up their work on innovations in all the different areas that can contribute to making travelling a more enjoyable and reassuring experience. In the course of the 21st Century, the automobile is poised to become part of a more global mobility system in which intermodal transport will be another decisive factor by allowing consumers to maintain the same relationship with their immediate environment while travelling, as well as the same quality of life as they enjoy when undertaking other activities.

The projects that Renault is working on in this domain explore many different types of breakthrough solutions – from new technologies and usages, to new business models – with the focus on making new comfort- and wellbeing-related features an affordable reality. Renault believes that these breakthrough solutions need to be simple, intuitive, cost effective and personalisable in line with the brand’s image.

The rising of new connected services

By combining connectivity with new mobility services, the automobile is in the process of becoming part of a multi-connected mobility system (vehicle-to-vehicle, vehicle-to-infrastructure, vehicle-to-cloud, etc.).

Connected services are being developed along two main lines :

- making information available to drivers and passengers in real time

- making sure that the transition between the different worlds in which they are active is as seamless as possible.

Safety while on the move is of fundamental importance, however. Connectivity and mobility systems need to be adapted to match the unique requirements of automotive use which calls for the development of specific controls and usability, plus vehicles that permit driving to be delegated in association with connected services.

Once this condition is met, there are no limits to what can be achieved in the future. Beyond one-off experiments, it is possible to imagine the advent in a few years’ time of vehicles that are not only fully-connected (car-to-car, car-to-grid, car-to-cloud) and autonomous, but also completely safe.

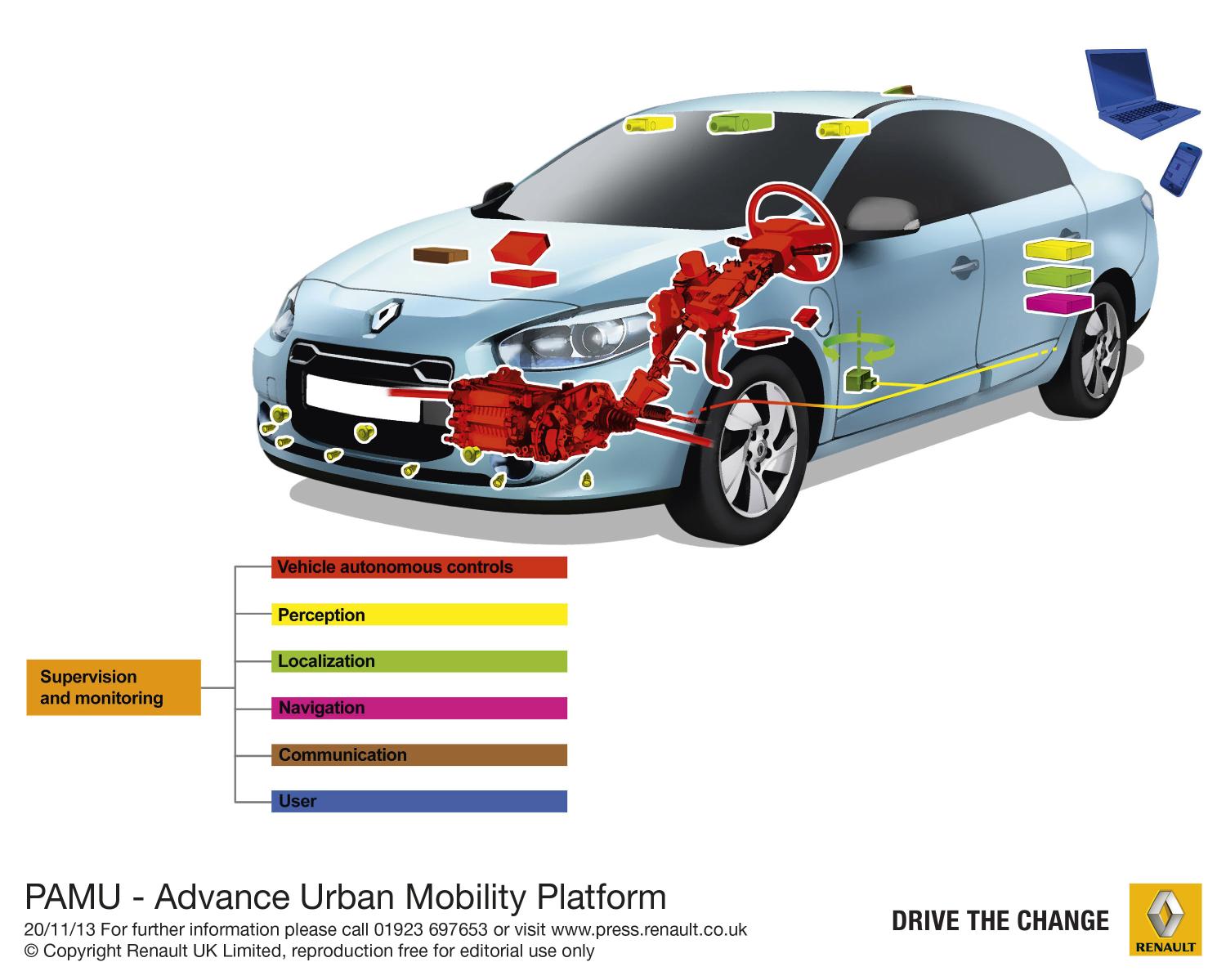

1. PAMU (ADVANCE URBAN MOBILITY PLATFORM)

The autonomous ‘valet’ service

HOW DOES IT WORK?

The objective of this project is to run an electric vehicle on automatic pilot, without passengers, in a controlled environment. The automatic mode could be used to steer the vehicle from a car park or charging station to a location selected by the user.

The PAMU project comprises four main functions:

- Perception of the vehicle’s immediate environment thanks to sensors and cameras.

- Computer-controlled chassis management.

- Geo-positioning thanks to the vehicle’s navigation system.

- A remote surveillance and services management system which communicates with the vehicle.

All the sensors and activators employed are mainstream automotive components.

Partners:

Conseil Général des Yvelines, UTC, ENSTA, IFSTTAR, Mobileye, Bosch, Acumine, Tecris, Viveris.

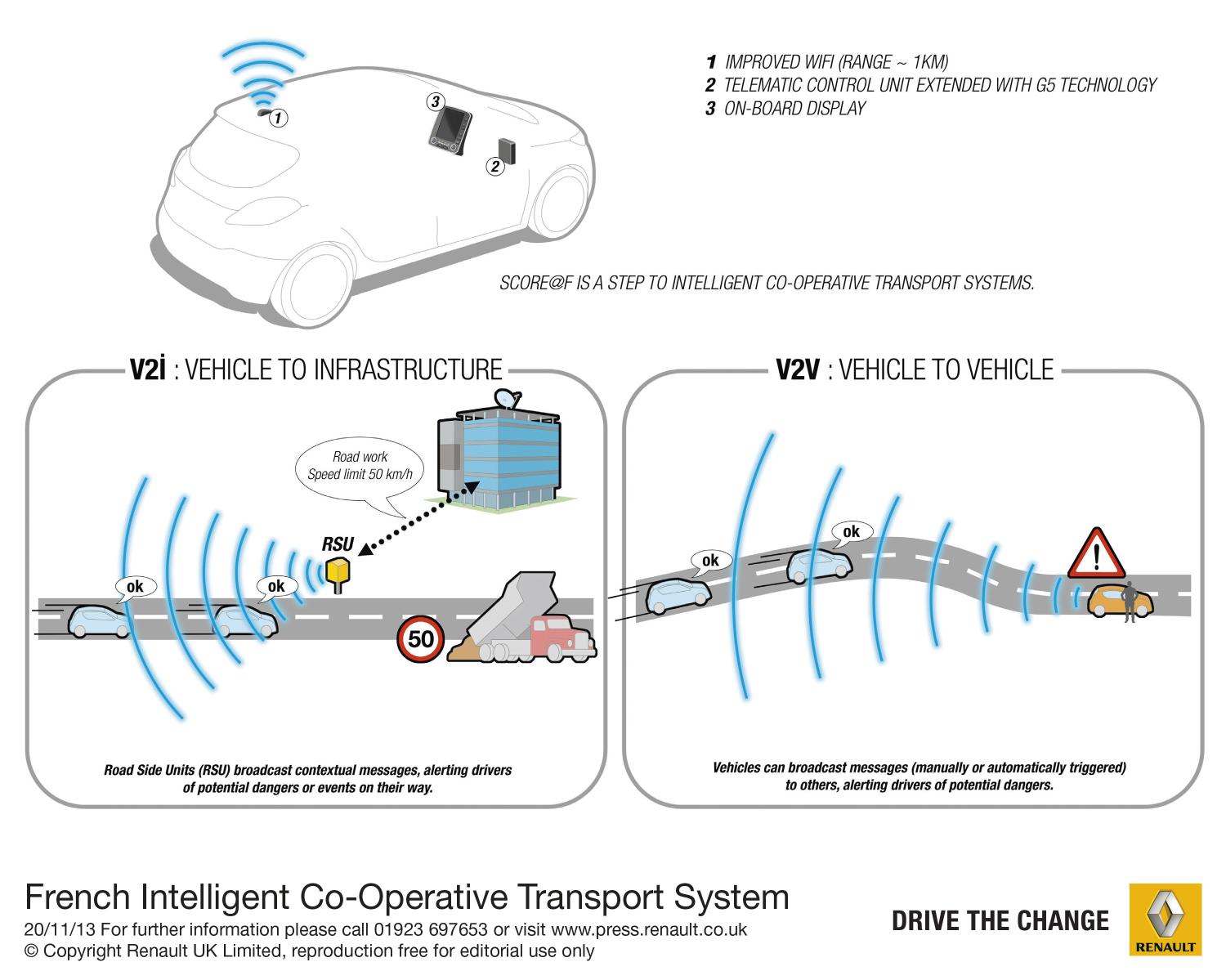

2. SCORE@F (INTELLIGENT CO-OPERATIVE TRANSPORT SYSTEM):

Real-time vehicle-to-vehicle and vehicle-to-infrastructure information for enhanced safety

HOW DOES IT WORK?

Cooperative systems are founded on a combination of continuous information-streaming and the communication of one-off messages between vehicles (V2V) and between vehicles and roadside infrastructure (V2I). They permit dangers to be detected and signalled to drivers in real time with a view to minimising the risk of an accident. Local communications are used in conjunction with high-speed local radio networks to permit multi-directional broadcasting of information within a radius of up to one kilometre around the transmitting station. The roadside units, which emit information at a frequency of 5.9GHz (imperceptible to humans), broadcast a host of safety-related information in addition to facilitating mobility and enhancing traveling comfort by providing drivers with travel- or sales-related information.

With time, these systems will be capable of contributing to safe vehicle automation.

Partners: PSA, Hitachi, Cofiroute, IFSTTAR, NEAVIA

Financial backing: Conseil Général des Yvelines, Conseil Général de l’Isère, CETE