YOKOHAMA, Japan (November 2, 2016) – Nissan Motor Co. Ltd., today introduced its new drive system called e-POWER to customers. It marks the first time that e-POWER technology is available for consumers, marking a significant milestone in the electrification strategy under Nissan Intelligent Mobility.

e-POWER borrows from the EV technology perfected in the Nissan LEAF, the best-selling pure electric car in history, with more than 250,000 units sold. Unlike the LEAF, e-POWER adds a small gasoline engine to charge the high-output battery when necessary, eliminating the need for an external charger while offering the same high-output.

The technology of e-POWER

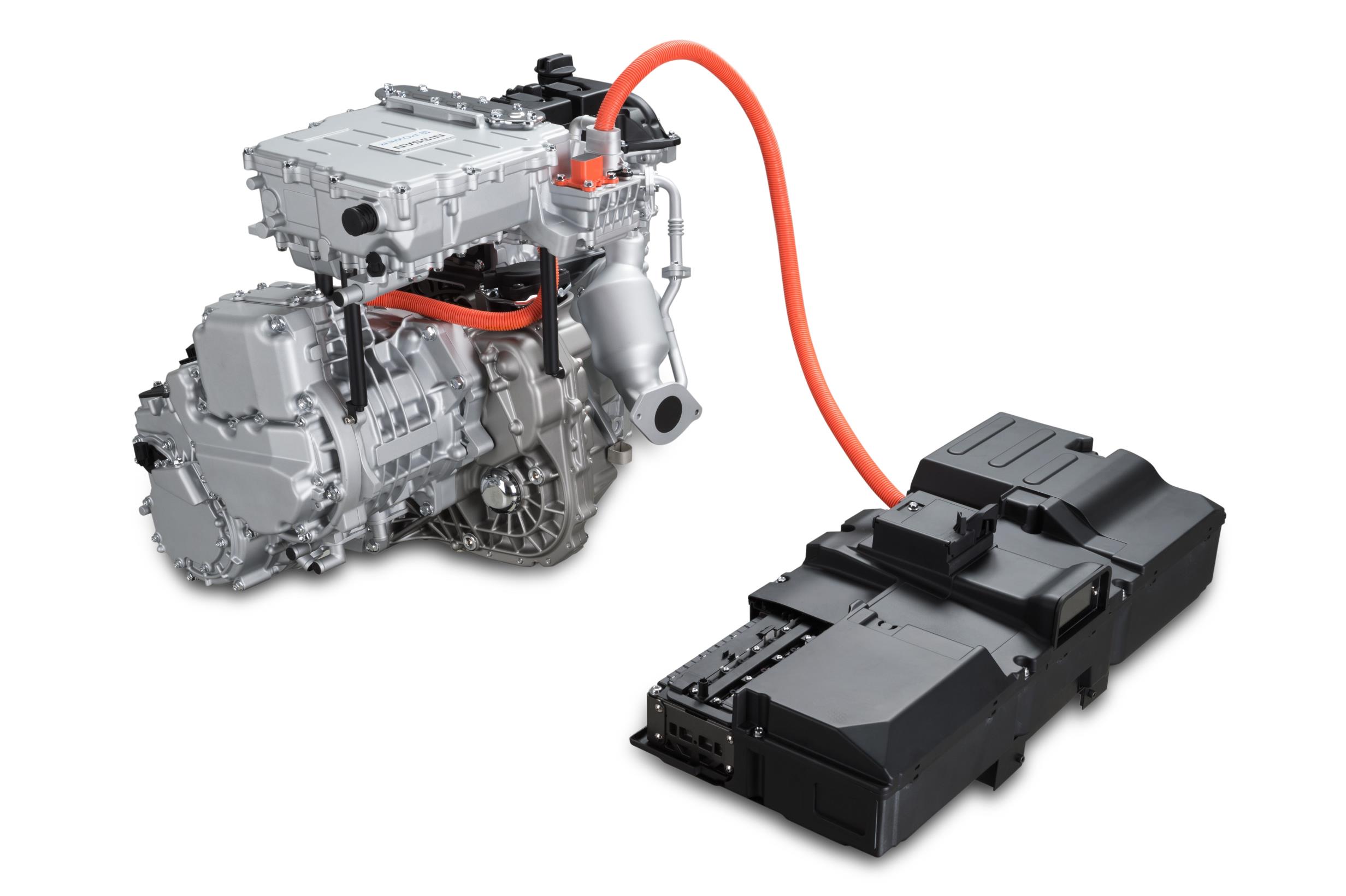

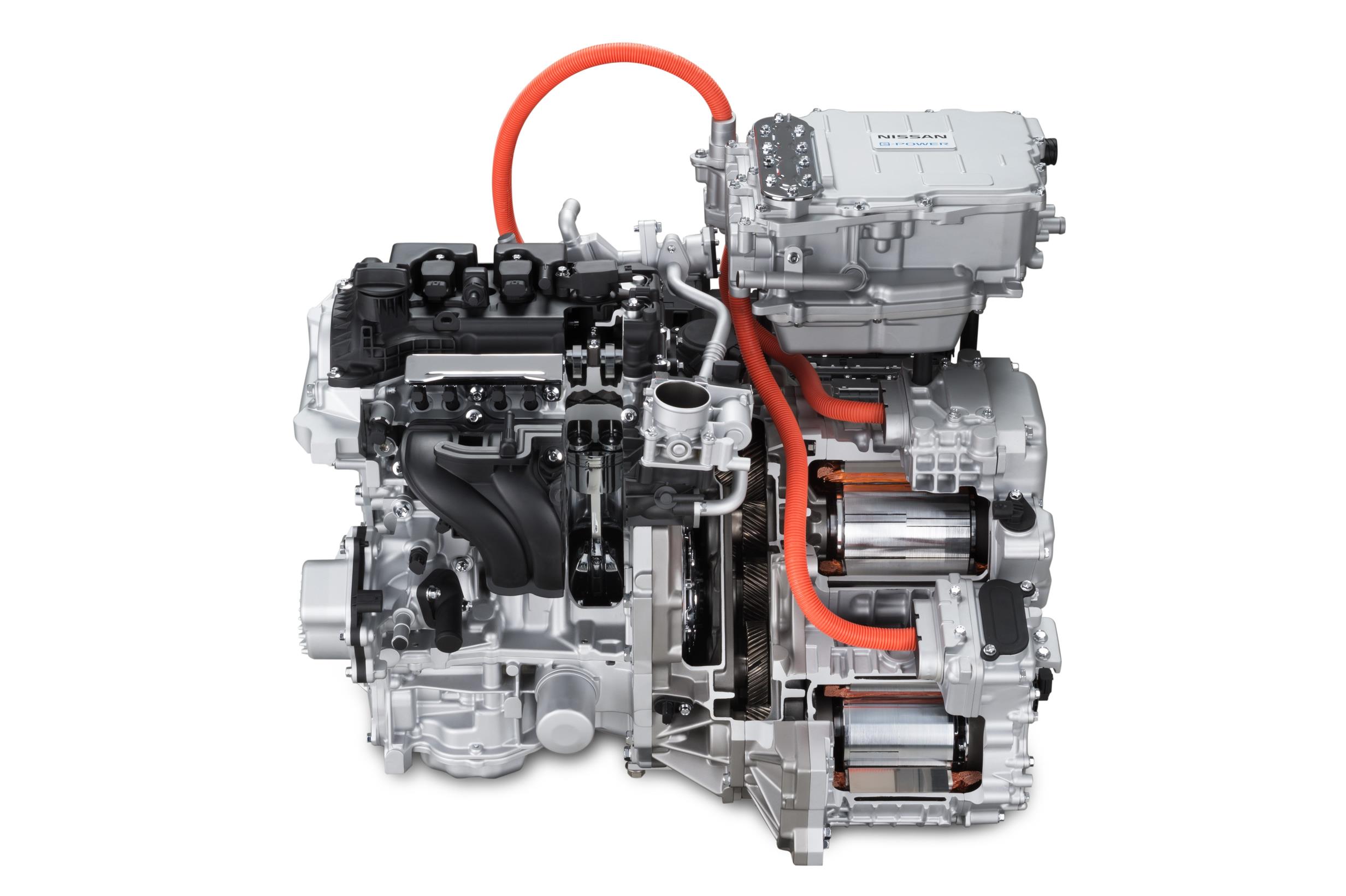

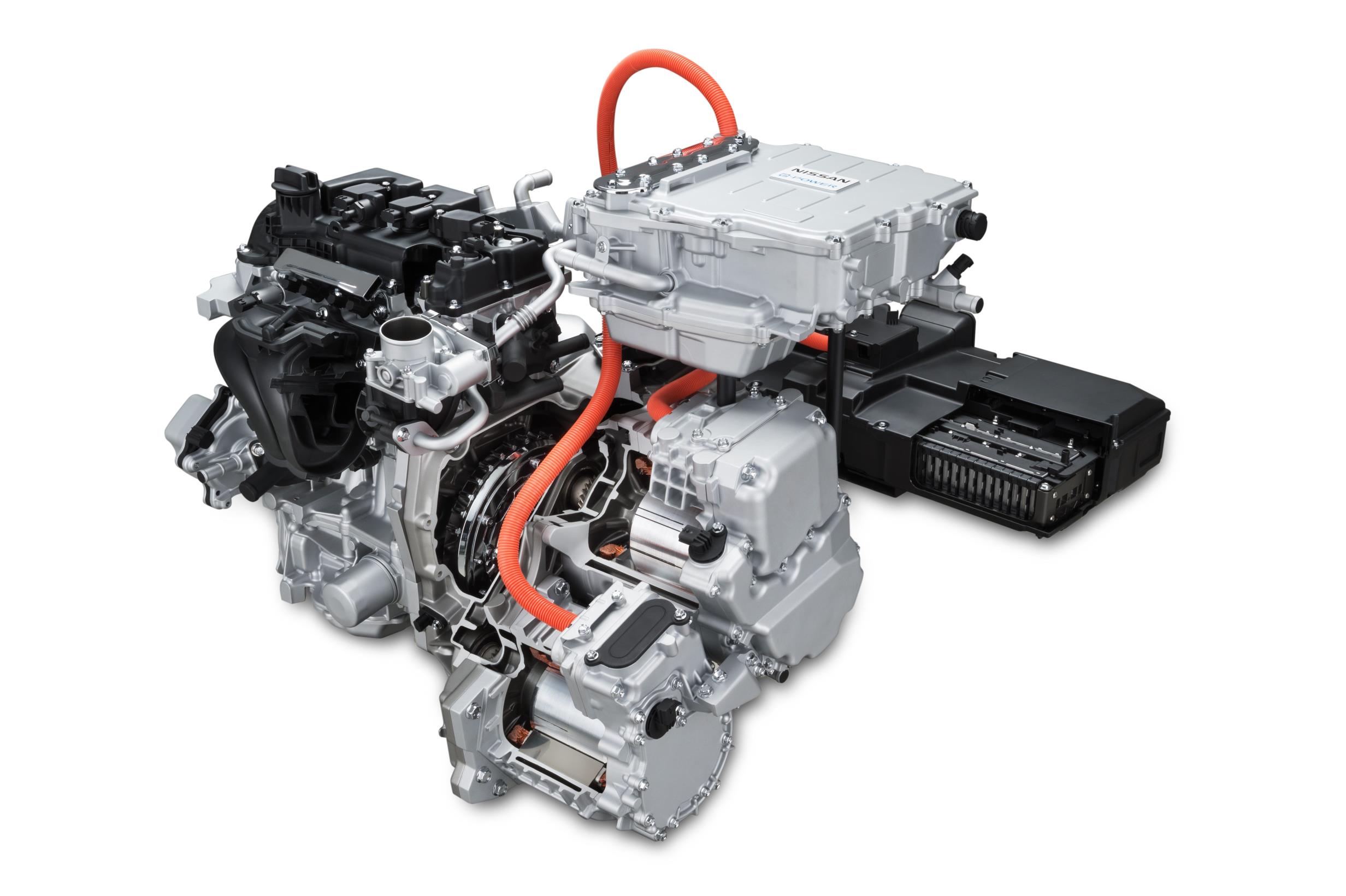

The e-POWER system features full electric-motor drive, meaning that the wheels are completely driven by the electric motor. The power from a high-output battery is delivered to the e-POWER’s compact powertrain comprised of a gasoline engine, power generator, inverter, and a motor. In conventional hybrid systems, a low-output electric motor is mated to a gasoline engine to drive the wheels when the battery is low (or when traveling at high speeds). However, in the e-POWER system, the gasoline engine is not connected to the wheels; it simply charges the battery. And unlike a full EV, the power source originates from the engine and not just the battery.

This system structure generally requires a bigger motor and battery because the motor is the only direct source to drive wheels. This has made it hard for the automotive industry to mount the system in compact cars. However, Nissan has cracked the code and learned how to minimize and reduce weight, develop more responsive motor control methods and optimize energy management. As a result, e-POWER uses a smaller battery than the LEAF, but delivers the same driving experience as a full EV.

The benefits of e-POWER

e-POWER delivers massive torque almost instantly, which enhances drive response and results in smooth acceleration. Also, the system operates very quietly, much like a full EV. Because e-POWER relies on the engine much less frequently, its fuel efficiency is comparable to that of leading conventional hybrids, especially during around-the-town commutes. The e-POWER system allows you to enjoy all the benefits of an EV without having to worry about charging the battery.

Development history

Nissan is actively pursuing a zero-emission, zero-fatality world for driving through its EV program and autonomous drive technology. To make this vision a reality, Nissan is developing “Nissan Intelligent Mobility,” which anchors critical company decisions around how cars are powered, how cars are driven, and how cars integrate into society, all while staying focused on creating more enjoyable driving experiences. e-POWER is another step towards achieving our zero-emission vision through a new and more efficient electric powertrain.

In 2006, Nissan experienced a breakthrough in its energy management technology. Nissan’s engineers were able to reduce the battery capacity to match its competitors’ hybrid vehicles while still delivering desirable EV qualities, such as quietness and efficient energy use. In addition, application of Nissan’s technologies, such as the integration of a power-generating engine, electric motor drive for compact car use, strengthening of the powertrain’s rigidity and improvements in NVH levels, became the foundation of e-POWER and its implementation in the compact-car segment.

Nissan is committed to developing electric-powered powertrains that use various fuels to cater to the different requirements of the world’s markets. e-POWER is but one example of that quest and will strengthen Nissan’s lineup of electric-powered powertrains. Nissan is also conducting research and development of the SOFC (Solid Oxide Fuel Cell) fuel-cell vehicle, and will continue to introduce innovative new products into various areas and promote the worldwide use of EVs.

Note: The e-POWER system is classified as a series hybrid. The Note e-POWER represents the first mass-production compact segment car ever to be equipped with a series hybrid system.